In the selection of food stabiliser, Stabiliser E450 stands out for its versatility and functionality. In this blog, we’re mainly talking about two Stabiliser E450: E450(i) and E450(iii). Although they share a similar base structure, their applications and functionalities are distinct, contributing uniquely to the food industry.

Introduction to E450(i) and E450(iii)

E450(i), or disodium dihydrogen pyrophosphate, is commonly found in bakery products. It controls the rate of fermentation and helps with dough handling.

E450(iii), or tetrasodium diphosphate, is predominantly used in canned seafood, processed cheese, and some meat products. It maintains color and texture in foods, especially in processed seafood.

Comparison of E450(i) and E450(iii)

Functions

Stabiliser E450(i): Fermentation control, improved dough handling, finer crumb structure.

Stabiliser E450(i): Fermentation control, improved dough handling, finer crumb structure.

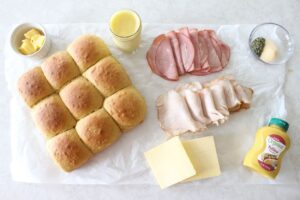

When it comes to bakery products, E450(i) is the go-to Stabiliser. It serves the critical function of controlling fermentation, an essential step in bread-making. By managing yeast activity, it ensures that the bread rises consistently and offers excellent dough handling. This uniformity is vital for commercial bakery operations, where the consistency of end-products is key.

Stabiliser E450(iii): Color preservation, texture stabilization, and prevention of oxidation.

In contrast, E450(iii) serves a different but equally vital function. It specializes in preserving the color and texture of food products. In the case of canned seafood, this means keeping the fish looking fresh and firm, rather than allowing it to become discolored or mushy. The use of E450(iii) ensures that the product remains visually appealing, a critical aspect of consumer satisfaction.

Mechanism of Action

E450(i): It functions by slowing down the fermentation process, thereby controlling the yeast’s activity. This gives the dough more time to rise and stabilize, leading to a finer crumb structure in baked goods.

E450(iii): This Stabiliser works by forming chelates with metal ions in the food. This prevents oxidation and maintains the color and texture of the food, primarily in seafood and processed cheeses.

Advantages

E450(i): Ensures consistency in bakery products, allows for large-scale production, and contributes to a better texture in baked goods.

E450(iii): Increases the shelf-life of products, improves consumer appeal by maintaining color and texture, and allows for broader distribution of products without compromising quality.

Can Stabiliser E450(i) Replace E450(iii) and Vice Versa?

Comprising two main variants, Stabiliser E450(i) and Stabilise rE450(iii), it often raises questions regarding their interchangeability. Can one replace the other without affecting the final product’s quality?

Assuming one could replace the other might lead to undesired results:

Replacing Stabiliser E450(i) with Stabiliser E450(iii) in Bakery Products: Introducing Stabiliser E450(iii) into bakery items might not offer the desired fermentation control. This could result in inconsistencies in the rise of the dough and potentially alter the texture of the baked product.

Using Stabiliser E450(i) in Place of Stabiliser E450(iii) for Seafood and Cheeses: E450(i) might not effectively retain the color and texture of seafood or processed cheeses, leading to diminished product appeal and possibly reduced shelf life.

Overall, both Stabiliser E450 are invaluable, offering distinct advantages in their respective applications. As each form of Stabiliser E450 has its merits, the key is to select the right variant based on specific requirements to ensure optimal results.

For Stabiliser E450, please reach out to [email protected].