1) Why Frozen Shrimp Loses Moisture During Transport, Thawing, and Cooking

Shrimp muscle is naturally high in moisture, but the water is not all “locked in” the same way it is in some red meats. The structure is delicate, and processing steps can easily damage the protein network that holds water. Once this happens, moisture migrates out of the muscle (drip loss), and the product feels drier after thawing and cooking.

In real production and logistics, moisture loss is usually driven by a combination of factors rather than one single cause:

- Freezing stress: ice crystal formation can disrupt muscle fibers, creating channels for water to escape during thawing.

- Freeze–thaw cycles: temperature fluctuations in transport or cold storage accelerate protein denaturation and drip loss.

- Salt and pH imbalance: the wrong ionic conditions can reduce water-holding capacity and weaken texture.

- Over-processing: excessive soaking time, aggressive mixing, or unsuitable additives can cause softening and increased purge later.

- Cooking loss: heat causes protein contraction; if the structure is not stabilized, water is expelled and yield drops.

For buyers, the impact is measurable and commercial: lower net weight after thawing, higher cooking shrink, more liquid in packaging, and customer complaints about dryness or inconsistent bite. This is why shrimp processors increasingly treat moisture management as a “system design” problem—raw material + process + functional additives + verification—rather than simply adding one chemical and hoping for a yield increase.

2) What a “Weight Gained Agent” Should Achieve in Shrimp Processing

In procurement language, “weight gain” often sounds like a single number. In processing reality, a professional weight gained agent solution should deliver a balanced set of outcomes—because weight gain that disappears during thawing is not a true commercial gain.

A high-performing shrimp weight gained agent typically targets four results at the same time:

- Increase water uptake efficiently during soaking or treatment (target: ≥20% weight gain under validated conditions).

- Hold water through freezing and thawing (target: thawing loss ≤5% with consistent batch-to-batch performance).

- Maintain natural texture (firm, elastic bite; avoid mushy or overly “rubbery” mouthfeel).

- Reduce cooking loss to protect yield at the customer’s kitchen or factory line.

That is why modern shrimp yield solutions are usually compound systems rather than single ingredients. The system is designed to manage pH, ionic strength, and protein stability—while also fitting market requirements such as “phosphate-free” labeling for certain export channels.

From a buyer’s perspective, the best way to evaluate a weight gain system is not “price per kilogram,” but cost-in-use: the dosage needed, the yield actually retained after thaw/cook, and the reduction in claims or downgrades. A slightly higher-cost additive can be cheaper overall if it reduces purge, stabilizes quality, and prevents rejection.

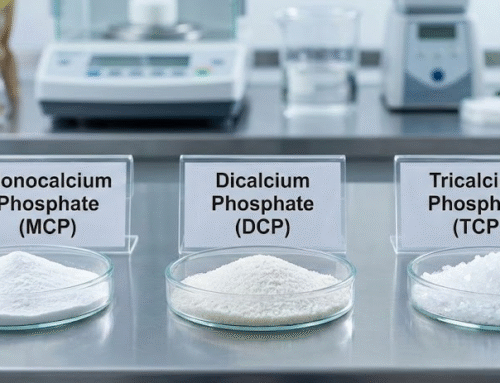

3) Two Solution Routes: Phosphate Systems vs Phosphate-Free Systems

In the seafood industry, phosphate systems remain the mainstream choice globally because they are reliable, economical, and well understood. At the same time, premium export markets and clean-label programs increasingly request phosphate-free solutions. This creates a “dual-market reality” in shrimp processing: many processors need both a phosphate route and a phosphate-free route to serve different customers.

In practical sourcing terms, you can think of shrimp moisture retention solutions as two product lines:

- Phosphate-containing compound blends (commonly based on E450/E451 families) for strong water binding, yield increase, and robust freeze–thaw performance.

- Phosphate-free compound acid / moisture retention systems (commonly based on carbonates, bicarbonates, citrates, and protective carbohydrates) for clean-label requirements and controlled, natural texture.

Both routes can be engineered to support your performance targets (≥20% absorption and ≤5% thaw loss), but they may differ in sensory profile, labeling, and the processing window needed for stable results.

4) Phosphate-Containing Compound Solution (For Mainstream Markets): Key Specs & Usage

For many shrimp processors, a phosphate-containing compound blend is still the most efficient path to stable yield improvement—especially when the customer does not require “phosphate-free” labeling. These blends are designed to improve water binding, protect texture, stabilize appearance, and reduce moisture loss over shelf life.

One typical shrimp-focused blend is formulated from sodium and potassium phosphates and includes E450 and E451 families. According to the product specification and usage guidance, core parameters commonly include the following:

| Item | Specification |

|---|---|

| Appearance | White powder |

| P2O5 content (%) | 54–60 |

| pH | 8.0–10.0 |

| As (ppm) | ≤ 1 |

| F (ppm) | ≤ 10 |

| Heavy metals (ppm) | ≤ 20 |

| Loss on drying (%) | ≤ 2.0 |

| Chloride (%) | ≤ 0.25 |

| Sulfate (%) | ≤ 0.05 |

The recommended dosage is 0.3–0.5% calculated based on raw material weight, and typical shelf life is 24 months in original packaging stored dry and cool.

4.1 Functional Advantages Buyers Care About

In shrimp processing, phosphate compound blends are often selected for these practical advantages: significantly increasing yield and water binding during processing and freezing, preventing drip and moisture loss during shelf life, stabilizing color/taste/appearance, and supporting tenderness and flavor stability.

When managed correctly, this type of phosphate-based weight gained agent system is well suited to IQF shrimp lines, export frozen shrimp, and customers who evaluate suppliers primarily on net yield, glaze stability, and consistent eating quality.

4.2 How to Use It to Target ≥20% Absorption and ≤5% Thaw Loss

While the blend dosage range is typically 0.3–0.5% on raw weight, the final results depend on your soaking solution concentration, salt synergy, water temperature, agitation, and soaking time. Your technical team should validate the “best point” by running structured trials measuring: raw weight, post-treatment weight, post-freeze weight, post-thaw drained weight, and cooked weight. This is the only reliable way to prove that water gain is retained and thaw loss stays below 5% across batches.

5) Phosphate-Free Compound Acid / Moisture Retention Solutions: Key Specs & Usage

Phosphate-free solutions are increasingly requested for premium export programs and clean-label positioning. These systems do not rely on phosphorus-containing compounds; instead, they use multi-component functional chemistry to achieve moisture retention, texture improvement, and freeze protection through buffering, mild alkalinity control, chelation, and protein stabilization.

Below are two common phosphate-free directions that shrimp processors use when they need a phosphate-free weight gained agent route.

5.1 Phosphate-Free Compound Acidity Regulator (Seafood Focus): Typical Composition & Properties

A representative phosphate-free compound acidity regulator for aquatic products can include sodium bicarbonate, sodium citrate, sodium carbonate, citric acid, and salt in defined ratios. A typical specification includes appearance (off-white powder), odorless, pH 7.0–9.0, and low heavy metal controls (e.g., arsenic 2 ppm max; heavy metals as Pb 2 ppm max). Key functional properties can include: phosphate-free positioning, fast water absorption, prevention of shrinkage after frying, no off-taste, improved tenderness, and tolerance of high-temperature cooking processes such as sterilization at 121°C. Recommended usage can be in the range of 1%–3% of final products depending on actual demand, with shelf life commonly 24 months.

For shrimp processors serving clean-label buyers, this type of compound acidity regulator is often used to support weight gain and reduce cooking shrink while keeping texture closer to “natural shrimp” rather than the stronger firmness profile sometimes associated with phosphates.

5.2 Phosphate-Free Compound Acidity Regulator (Fast Dissolving, High Water Absorption): Usage Guidance

Another phosphate-free compound acidity regulator approach is positioned specifically for aquatic products such as shrimp and fish and emphasizes fast dissolution speed and superior water absorption compared to conventional solutions. Typical application guidance can include: using a 2.5%–4.0% solution for soaking with 1%–1.5% salt as support, or using 0.8%–2.0% of total weight for tumbling. A typical pH range is 8.00–9.20, with the product described as suitable for improving water retention, enhancing texture, and increasing weight in aquatic products.

If your plant’s main pain point is “water gain that disappears after thaw,” this route often improves retention by combining buffering control with process discipline (cold water control, correct soak time, and a stable salt strategy).

5.3 Phosphate-Free Moisture Retention System (Carbonate + Citrate + Protective Carbohydrates)

A more “system-level” phosphate-free moisture retention product can be described as a compound acidity regulator manufactured with modern food processing technology and free from phosphorus-containing compounds. Typical main components include food-grade carbonates, citrates, and natural polysaccharides, with functions including enhanced water-holding, texture improvement, inhibition of freeze-induced protein denaturation, and reduction of cooking loss.

Key specification points can include moisture ≤2.0% and pH 8.0–9.0 (1% solution), plus limits for arsenic and lead. Recommended usage methods may cover injection/tumbling, soaking/marinating (e.g., 2.0%–3.0% marinating solution), and direct mixing depending on the seafood format.

For export programs that explicitly request “phosphate-free,” this type of system supports moisture retention while aligning with clean-label expectations, especially when combined with disciplined cold-chain handling and validated trial data.

6) How to Reach ≥20% Water Absorption and ≤5% Thaw Loss: Process Checklist

Whether you choose phosphate blends or phosphate-free systems, your plant results depend heavily on process control. Below is a practical checklist your technical team can use to achieve the performance targets consistently.

6.1 Define Your Test Metrics Before You Start

- Weight gain (%): (post-treatment weight − raw weight) ÷ raw weight × 100.

- Thaw loss (%): (frozen net weight − thawed drained weight) ÷ frozen net weight × 100.

- Cooking loss (%): (thawed drained weight − cooked weight) ÷ thawed drained weight × 100.

Only when you track all three can you confirm that the “weight gain” is real and retained through thawing and cooking.

6.2 Control the Water Temperature and Mixing

Cold brine (0–4°C) protects food safety but can slow dissolution for certain systems. If your process uses cold water, select solutions designed for fast dissolution and ensure mixing is sufficient to avoid undissolved particles and uneven concentration zones. Uneven brine is a common hidden cause of inconsistent yield and patchy texture.

6.3 Use Salt as a Functional Partner (Not Just a Flavor Ingredient)

Many shrimp yield systems perform better when salt is applied in a controlled range because ionic strength supports water binding and improves functional performance. For phosphate-free soaking solutions, guidance often recommends salt support (for example, 1%–1.5% salt paired with a 2.5%–4.0% soaking solution in certain approaches).

6.4 Prevent Over-Treatment

More additive is not always better. Over-treatment can lead to soapy taste, abnormal softness, or a “processed” mouthfeel. The correct strategy is to determine the minimum effective dosage that achieves ≥20% absorption while keeping thaw loss ≤5% and texture acceptable for your target market.

6.5 Validate Across Different Raw Material Lots

Shrimp size, species, harvest season, and pre-processing conditions affect absorption and retention. A professional supplier evaluation should include multiple raw material lots and at least 2–3 production days to confirm stability, not just a single lab test.

7) Application Scenarios: IQF Shrimp, Cooked Shrimp, and Export Channels

7.1 IQF Shrimp (Raw, Frozen)

IQF shrimp is highly sensitive to thaw drip because the surface area is large and freezing is rapid. For mainstream markets, phosphate blends are often preferred because they deliver strong water binding and freeze–thaw robustness. For clean-label programs, phosphate-free compound systems are used to support water retention while keeping texture closer to natural shrimp.

7.2 Cooked Shrimp (Value-Added, Ready-to-Eat)

Cooking is a major “stress test.” If your current weight gain disappears during cooking, you may need a system that improves water-holding while also reducing cooking loss. Phosphate-free systems that combine buffering control with protective components can help stabilize proteins and reduce cooking shrink when used correctly.

7.3 Export Programs with Label Requirements

Many processors operate two SKUs: one for mainstream global channels (phosphate allowed) and one for premium channels (phosphate-free requested). This dual portfolio reduces commercial risk: you can meet diverse buyer expectations without constantly redesigning your process.

For an overview of seafood application categories and additive solution directions, you can reference our category page: Food Additives For Seafood Processing.

8) Compliance & Buyer Notes: Additive Standards and Labeling

Buyers should confirm compliance based on the destination market and product category. In many countries, phosphates such as sodium tripolyphosphate are permitted for food use under defined conditions, often under “good manufacturing practice” and/or category-specific limits. In the United States, sodium tripolyphosphate is listed in the Code of Federal Regulations as generally recognized as safe when used in accordance with good manufacturing practice.

For international reference, the Codex Alimentarius General Standard for Food Additives (GSFA) provides a searchable database of permitted additives and conditions by food category and functional class, which is widely used for regulatory alignment and trade discussions.

Authoritative external reference: Codex GSFA Online Database (FAO/WHO).

Important note: final responsibility for regulatory compliance and labeling rests with the food manufacturer/exporter. A qualified supplier should provide specifications, COA consistency, and technical support, but your QA and regulatory team should verify compliance for the target market.

9) Buyer FAQ: What Data to Request Before Ordering

If you are sourcing a shrimp weight gained agent system and want predictable results (≥20% absorption and ≤5% thaw loss), use the checklist below during supplier evaluation:

- Specification sheet: pH, key contents, impurity limits, moisture, solubility, shelf life, packaging.

- Recommended dosage and application method: soaking concentration, salt synergy, time, temperature, agitation requirements.

- COA stability: multiple batch COAs to confirm consistency.

- Trial protocol: supplier should propose a measurable plant trial plan with defined metrics (weight gain, thaw loss, cooking loss, texture).

- Market fit: phosphate or phosphate-free option depending on your customer labeling requirement.

If a supplier can only talk about “yield increase” but cannot define test methods and conditions, the risk of inconsistent results is high. Professional sourcing should be evidence-driven and process-matched.

10) Conclusion & Inquiry: Build a Dual-Portfolio for Different Markets

Frozen shrimp moisture loss during transport, thawing, and cooking is not inevitable. With the right compound system and correct process control, shrimp processors can achieve strong commercial outcomes such as water absorption ≥20% and thawing loss ≤5%, while protecting texture and customer acceptance.

The most practical strategy today is a dual portfolio: phosphate-containing blends for mainstream markets that value maximum yield and robust freeze–thaw stability, and phosphate-free compound acid/moisture retention systems for clean-label export programs that require phosphate-free labeling and a more natural sensory profile.

To explore more seafood additive options and application categories, visit: Food Additives For Seafood Processing.