Phosphate-free seafood additive solutions are increasingly required in premium export markets, even though traditional phosphate systems remain the backbone of global seafood processing.

For more than 40 years, phosphates have enhanced water retention, improved texture, increased yield, prevented thawing loss, and maintained firmness in shrimp, fish fillets, squid, scallops, and surimi.

While phosphates continue to be the most reliable and economical option for mainstream markets, regulatory trends and clean-label expectations in Japan, Kore,a and certain EU channels have created a growing need for phosphate-free seafood products.

Our company supports this dual-market reality by supplying two complete product lines: high-quality phosphate ingredients for mainstream seafood processors, and a phosphate-free moisture retention system designed specifically for clean-label seafood applications.

1) Why Phosphates Remain Mainstream in Seafood Processing

Although the global market is gradually increasing interest in phosphate-free solutions, phosphates such as STPP, TSPP And SHMP remains the primary functional additive used in the seafood industry worldwide. Their dominant role is due to their unmatched performance in:

- Water retention: Increasing moisture uptake in shrimp, fish and squid.

- Texture enhancement: Improving firmness and bite.

- Freeze–thaw stability: Preventing protein denaturation and thawing drip.

- Yield improvement: Increasing finished product weight and reducing dehydration loss.

- Color and translucency preservation: Particularly valuable in shrimp and squid.

In many regions — Asia-Pacific, Middle East, Latin America — phosphates are not only allowed but preferred by both factories and customers due to their consistent performance and cost efficiency.

2) Why Certain Markets Now Request Phosphate-Free Seafood

The movement toward phosphate-free seafood is driven by market demands rather than technical necessity. The primary reasons are:

2.1 Clean-Label Expectations from Consumers

Retail consumers in Japan, Korea, and the EU increasingly associate food additives — particularly phosphates — with “processing”, even though phosphates are scientifically safe when used correctly.

2.2 Retailers’ Labeling Restrictions

Major supermarkets in Japan and South Korea prefer seafood labeled as:

- “無添加” (additive-free)

- “phosphate-free”

- “clean label”

2.3 Export Compliance Requirements

For certain export programs, especially premium-quality frozen shrimp or fish fillets, buyers may specify:

2.4 Sensory Expectations in Premium Markets

Some markets prefer a more “natural” seafood bite, less firm than phosphate-treated products. For these markets, phosphate-free systems can provide a closer-to-natural texture.

3) Seafood Muscle Science: Why Seafood Requires Special Functional Chemistry

Unlike pork or poultry, seafood muscle structure is extremely delicate. Understanding seafood protein science is essential to understand why both phosphate and phosphate-free systems must be formulated differently.

3.1 Lower Salt-Soluble Protein Content

Shrimp and fish contain less myofibrillar protein compared to land animals, making them more susceptible to dehydration.

3.2 Soft Muscle Fibers

Seafood tissue easily fractures during freezing, thawing and handling, requiring functional additives to protect structure.

3.3 Higher Water Mobility

Water is held more loosely in seafood muscle, increasing the risk of:

- thaw drip

- loss of firmness

- white spots or “chalkiness” in shrimp

3.4 Faster Protein Denaturation During Freezing

This is the main reason frozen seafood often becomes dry or rubbery if not treated with proper moisture retention systems.

4) Technical Challenges in Developing a Phosphate-Free System for Seafood

Creating a phosphate-free water retention system for seafood is significantly more challenging than for meat products. This is because phosphates perform multiple roles simultaneously:

- raising pH

- chelating metal ions

- solubilizing proteins

- stabilizing muscle structure

- enhancing freeze–thaw resistance

Replacing these functions without phosphorus requires a multi-component strategy.

4.1 pH Adjustment Without Excess Alkalinity

Seafood is extremely sensitive to pH changes. Too much alkalinity results in:

- soapy taste

- excessive softening

- loss of natural texture

4.2 Preventing Drip Loss Without Phosphate Binding

Seafood muscle has weak water-binding ability, so phosphate-free formulation must compensate using:

- buffer salts

- mild alkalinity

- protein-protective carbohydrates

4.3 Freeze–Thaw Stability Without Polyphosphate Chains

Trehalose plays a major role here, but must be precisely balanced with carbonate and citrate.

5) Our Two-Track Product Strategy: Supplying Both Phosphates and Phosphate-Free Additives

We supply the global seafood industry with both solutions because both remain essential:

5.1 Phosphate-Based Products (Mainstream)

We supply food-grade STPP, TSPP, SHMP, and blended phosphates, which remain:

- The global standard for shrimp processing

- the most cost-effective option

- preferred in markets without additive restrictions

5.2 Phosphate-Free Product (L38) — Designed for Seafood

Our phosphate-free agent is used exclusively in seafood processing and supports factories targeting:

- Japan

- South Korea

- EU premium retail

- brands requiring “no added phosphates.”

6) Ingredient Technology Behind Our Phosphate-Free System

6.1 Sodium Carbonate

Provides mild alkalinity to increase pH slightly, helping seafood proteins bind more water.

6.2 Sodium Bicarbonate

Offers pH buffering, preventing over-alkalization while stabilizing ionic conditions.

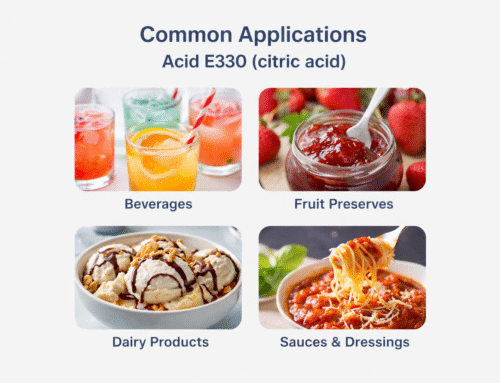

6.3 Sodium Citrate

A natural-origin chelating agent that:

- controls metal ions

- improves muscle integrity

- enhances juiciness

6.4 Trehalose

A powerful cryoprotectant used widely in seafood to:

- inhibit freeze denaturation

- reduce drip loss

- Protect the natural bite of shrimp and fish

7) Functional Mechanisms of L38 in Seafood Applications

L38 does not attempt to replicate the phosphate molecule-for-molecule. Instead, it reproduces the key functional results required by seafood processors:

7.1 Improved Water Retention

The carbonate–bicarbonate–citrate system opens the protein structure sufficiently to hold moisture without excessive swelling.

7.2 Freeze–Thaw Protection

Trehalose interacts with water molecules to prevent ice crystal damage.

7.3 Drip-Loss Reduction

L38 stabilizes muscle protein–water interactions, minimizing dehydration during thawing and storage.

7.4 Texture Maintenance

Ensures seafood remains firm yet natural, suitable for premium retail markets that avoid the “too firm” phosphate texture.

8) Phosphate vs Phosphate-Free: Technical Comparison in Seafood Processing

| Aspect | Phosphates | Phosphate-Free (L38) |

|---|---|---|

| Primary Function | Strong water binding, strong firmness | Mild water retention, natural texture |

| Freeze–Thaw Stability | Very strong | Excellent (trehalose-based) |

| Market Acceptance | Global mainstream | Japan, Korea, EU premium |

| Labeling | Shows phosphates | Phosphate-free |

| Texture | Very firm | More natural |

9) Application Scenarios

9.1 Shrimp

L38 prevents:

- black spot development

- surface dehydration

- thaw drip

- loss of translucency

9.2 Fish Fillets

Helps maintain:

- surface moisture

- flake integrity

- cooking yield

9.3 Squid & Cuttlefish

L38 provides anti-dehydration properties without increasing firmness too much, which is often disliked in the Japanese market.

9.4 Scallops

Helps maintain a round shape and firmness after thawing.

10) Export Regulations & Labeling Differences

Different markets treat phosphates differently:

- Japan: Prefers additive-free seafood; phosphates are discouraged in retail products.

- Korea: Similar clean-label trend for frozen seafood.

- EU: Allowed but must meet maximum P2O5 limits.

- USA: GRAS; widely used in shrimp processing.

11) Buyer Decision Model: How to Choose

Whether to use phosphates or phosphate-free depends entirely on your customer base.

| Situation | Recommended Solution |

|---|---|

| Export to Japan/Korea | L38 Phosphate-Free System |

| Export to EU premium retailers | L38 or low-dose phosphates |

| Export to the US | Phosphates (STPP/TSPP/SHMP) |

| Middle East / Latin America | Phosphates |

| OEM project requiring a clean-label | Phosphate-Free (L38) |

12) Conclusion: Two Solutions for a Diversified Seafood Market

The future of seafood processing is not “phosphate vs phosphate-free”. It is a dual-solution approach that allows processors to adapt to different export requirements.

Our company supports this global shift by supplying:

- Complete phosphate product line for mainstream markets

- Phosphate-free L38 system for clean-label, premium export markets

By offering both systems, we help seafood processors:

- enter new markets,

- increase product premium value,

- improve yield and quality,

- comply with regulations,

- and meet diversified buyer expectations.