Acidity regulator choice is one of the most important formulation decisions in modern food processing.

The right system will quietly stabilise pH, support flavour and microbiological safety, protect colour and texture, and even reduce overall cost in use. The wrong one can cause harsh sourness, protein precipitation, syneresis, weak preservation and label or regulatory challenges.

In practice, technologists rarely use a single acid. Most successful formulations combine organic acids and their salts, sometimes with inorganic sources, to create a tailored acidity profile for a specific matrix and process. Understanding how each acidity regulator behaves is therefore essential if you want consistent quality from the lab to the factory line.

This article explains, in a practical and technically grounded way, how to select acidity regulators for different food categories, how to compare key organic acid systems (lactates, citrates, malates and ascorbates), where to source food grade citric acid, and how to design blended systems that deliver pH control together with flavour and antioxidant performance.

1) What Is an Acidity Regulator in Food Processing?

In international food additive terminology, an acidity regulator is an ingredient added to a food to control its acidity or alkalinity and to maintain a specific pH range during processing and shelf life. Compared to simple “acidulants”, acidity regulators often include both acids and buffering salts, so that they not only create sourness but also stabilise pH against drift caused by proteins, minerals, fermentation or storage.

For formulators, acidity regulators are multi-functional:

- pH control and buffering: keeping products within a safe and organoleptically acceptable range.

- Flavour shaping: defining the type of sourness (sharp vs soft, quick vs lingering) that consumers perceive.

- Microbiological safety and shelf life: supporting other hurdles such as heat, salt and preservatives.

- Texture and protein functionality: influencing casein micelles in dairy, gluten behaviour in bakery, and myofibrillar proteins in meat and seafood.

- Colour and antioxidant protection: especially where ascorbates are used in meat, beverages and fruit products.

Rather than asking “which acid is cheapest per kilogram”, it is more useful to ask: “Which acidity regulator system gives the best overall cost per tonne of finished product, while meeting flavour, texture, safety and labelling targets?”

2) Types of Acidity Regulators: Organic vs Inorganic Systems

Acidity regulators in food processing can be broadly divided into two families: (1) organic acids and their salts, and (2) inorganic acids and their salts. Both have legitimate roles, but their sensory profiles, buffering curves and consumer perceptions are very different.

2.1 Organic Acids and Their Salts – The Dominant Group

In most food categories, organic acid-based acidity regulators are the first choice. Typical examples include:

- Citric acid and sodium / potassium citrate.

- Lactic acid and lactates.

- Malic acid and malates.

- Ascorbic acid and ascorbates.

- Acetic, tartaric and fumaric acids in specific applications.

These ingredients are well understood, widely accepted by regulators and consumers, and often perceived as “milder” or “more natural” than strong mineral acids. They offer flexible pH control in the range typically required for beverages, fruit products, dressed salads, dairy, baked goods, sauces and processed meat.

2.2 Inorganic Acids and Salts – Functional but Less Versatile

Inorganic systems include phosphoric acid, sodium phosphates, sodium carbonate, sodium bicarbonate and related salts. They are indispensable in certain applications:

- Phosphoric acid in cola-type beverages to provide a sharp, clean acidity and support carbonation.

- Carbonates and bicarbonates as leavening agents and pH adjusters in bakery.

- Phosphate buffers in meat and seafood to stabilise proteins and water binding.

However, inorganic acids typically have less pleasant sourness on their own, narrower pH windows for flavour, and may face stricter perception issues in clean-label concepts. As a result, they are usually combined with organic systems rather than used as the sole acidity regulator.

3) Comparing Key Organic Acid Acidity Regulators

Among organic systems, four families of acidity regulators are especially important in day-to-day formulation work: citrates, lactates, malates and ascorbates. Each has a distinctive profile in terms of flavour, cost and side-functions.

3.1 Citric Acid and Citrates – The Workhorse Acidity Regulator

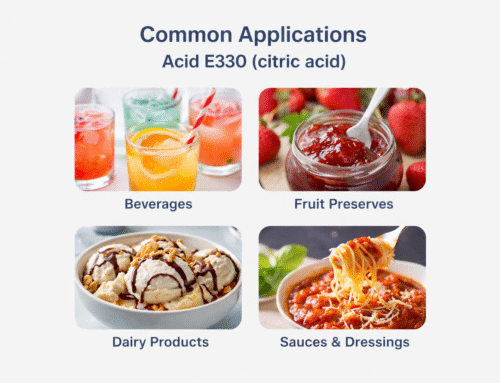

Citric acid (and its sodium or potassium salts) is the single most widely used acidity regulator in the food industry. It delivers:

- Clean, bright sourness suitable for beverages, candies, jams, sauces and dressings.

- Strong complexing ability with metal ions such as iron and copper, helping delay oxidation and colour loss.

- Good buffering in the pH 3–6 range when combined with citrate salts.

- Low cost per functional unit due to large global production scale.

For many formulators, citrate systems are the default starting point. Only when there is a specific sensory or functional requirement that citrates cannot meet do they explore alternatives.

3.2 Lactic Acid and Lactates – Mild, Dairy-Friendly Acidity

Lactic acid is naturally associated with fermented dairy products and certain pickled vegetables. As an acidity regulator it offers:

- Smoother, less aggressive sourness than citric acid, particularly useful in dairy drinks and dressings.

- Good compatibility with milk proteins, reducing the risk of precipitation compared with some stronger acids.

- Antimicrobial contribution in combination with lactates in meat and ready-to-eat products.

Lactic systems are usually more expensive than citrates on a per-kg basis, so they are often used in targeted ways where flavour or microbial performance justifies the cost.

3.3 Malic Acid and Malates – Long-Lasting Sourness

Malic acid delivers a distinctive “lingering” sourness that works very well in fruit-flavoured beverages and chewy candies. It has:

- Higher acid equivalent per kilogram than citric acid, allowing lower dosage in some formulas.

- A flavour profile reminiscent of many natural fruits, especially apple and berry.

- The ability to extend the perception of sourness, useful in reduced-sugar products.

In practice, formulators often blend malic and citric acids to balance “attack” and “aftertaste”, using citric for the initial impact and malic for the tail.

3.4 Ascorbic Acid and Ascorbates – Antioxidant Acidity Regulators

Ascorbic acid (vitamin C) and its salts are sometimes overlooked as acidity regulators because their primary role is antioxidant. However, they can contribute meaningfully to both pH adjustment and redox control in:

- Fresh and processed meat, to stabilise colour and delay lipid oxidation.

- Fruit beverages and juices, to protect aroma and colour.

- Bakery and cereal products, where dough conditioning is required.

Ascorbate systems are usually more expensive than simple acids, so they are rarely used alone for pH control. Instead, they are layered onto citrate or lactate systems to combine antioxidant and buffering performance.

3.5 Price and Effectiveness Overview

From a commercial standpoint, the ranking is often:

- Citrates: broadest application window, lowest cost, highest global acceptance.

- Lactates: more specialised, used where mild acidity and antimicrobial functions are needed.

- Malates: chosen for flavour and reduced-sugar challenges, with moderate cost.

- Ascorbates: premium functionality as antioxidants and colour protectors, used at lower dosage levels.

For most mainstream products, citrates form the backbone of the system, with other organic acids added in smaller amounts to fine-tune sensory and functional properties.

4) Regulatory and Labelling Framework for Acidity Regulators

Any acidity regulator strategy must respect regulatory limits and labelling rules in the target markets. Two widely referenced frameworks are:

- The Codex General Standard for Food Additives (GSFA) online database, which lists permitted food additives, including acidity regulators, by food category and functional class.

- National or regional positive lists, such as Health Canada’s List of Permitted pH Adjusting Agents and Acidity Regulators, which defines where and at what levels these additives may be used.

When selecting or changing an acidity regulator system, R&D and regulatory affairs should jointly verify:

- That each component is approved for the relevant food category.

- That the combined dosage of all additives remains within maximum permitted levels.

- How the ingredient will appear on the label (additive name vs E-number, “acidity regulator” vs “antioxidant”).

Early regulatory checks avoid costly reformulation or relabelling at a later stage, especially when exporting to multiple markets.

5) Application-Based Selection: Matching Acidity Regulators to Food Categories

Although the same ingredients appear in many formulations, the optimal acidity regulator system is highly dependent on the product matrix and process. Below is a practical overview for key food categories.

5.1 Beverages and Liquid Concentrates

For still and carbonated soft drinks, citric acid remains the primary workhorse, sometimes supported by malic or tartaric acid:

- Cola and dark sodas: often rely on phosphoric acid for a sharp, cola-specific profile, but may include citric acid to soften the attack and improve buffering.

- Fruit beverages: mainly citric and/or malic acid to match the target fruit flavour and desired sourness curve.

- Energy and vitamin drinks: citrate systems for pH and ascorbic acid for antioxidant and nutritional positioning.

For beverage concentrates and syrups, buffering capacity becomes more important to prevent pH drift after dilution, and citrate salts (e.g. trisodium citrate) are commonly used together with citric acid.

5.2 Jams, Jellies and Fruit Preparations

In high-sugar fruit systems, the acidity regulator must both stabilise pectin gel and control sweetness perception:

- Citrates support gelation and provide a familiar fruit-like sourness.

- Malic acid extends the sourness tail, especially useful in low-sugar or no-sugar-added formulations.

- Ascorbic acid can protect colour in oxygen-sensitive fruits.

5.3 Fermented and Dairy-Based Products

Dairy systems are particularly sensitive to pH. The wrong acidity regulator can cause protein precipitation, graininess or whey separation:

- Yoghurt drinks and fermented milks: lactic acid and lactates align with the inherent fermentation profile.

- Flavoured milk and cream beverages: mild citric–lactic blends keep pH away from the isoelectric point of casein.

- Processed cheese: citrate–phosphate buffers interact with emulsifying salts to maintain melt and sliceability.

5.4 Bakery Products and Snacks

In bakery, acidity regulators are often hidden within leavening and flavour systems:

- Baked cakes and muffins: acidulants such as tartaric, fumaric or sodium acid pyrophosphate are paired with bicarbonates to generate gas and control final pH.

- Savoury snacks and tortillas: citric and lactic acids can brighten flavour and support microbiological stability.

Here, the choice of system affects not only taste but also crumb colour, browning reactions and shelf life.

5.5 Sauces, Dressings and Condiments

Sauces and dressings are often oil-in-water emulsions or high-water, high-spice matrices. The acidity regulator must:

- Deliver target pH for microbial control (often below pH 4.1).

- Match flavour expectations (vinegar notes vs citrus vs lactic tang).

- Be compatible with stabilisers and emulsifiers.

Combinations of acetic acid (vinegar character) with citric or lactic acid are common, with citrate salts adjusting buffering and saltiness.

5.6 Meat and Poultry Products

In processed meat, the acidity regulator cannot be considered in isolation: pH must be managed together with protein extraction, water binding and colour stability. Sudden drops in pH can cause tough texture or purge in the package.

For many applications, formulators therefore use blended systems combining citrates, lactates, phosphates and ascorbates. These are designed to:

- Control pH in a narrow window that favours protein functionality.

- Enhance water-holding and yield.

- Contribute antioxidant and colour protection.

You can see examples of such functional blends in our meat and poultry processing solutions, where acidity regulation is integrated with phosphate technology, flavour and shelf-life design.

6) Where to Buy Citric Acid as an Acidity Regulator

Because citric acid and citrate buffers form the backbone of so many systems, secure sourcing is essential. When evaluating suppliers, consider:

- Food grade certification and compliance with relevant pharmacopeia or FCC standards.

- Particle size and flowability for your dosing equipment and dissolution requirements.

- Impurity profile, especially heavy metals and insoluble matter for beverage and high-clarity systems.

- Port warehouse availability for flexible logistics and shorter lead times.

GJ Phosphate supplies high-purity citric acid suitable as a primary acidity regulator in beverages, confectionery, bakery and processed foods. For product details and typical specifications, please visit our Citric Acid Monohydrate product page.

7) Designing Blended Acidity Regulator Systems

In many real-world applications, no single ingredient can deliver the full suite of required functions. Instead, formulators design blended acidity regulator systems that combine fast-acting acids, buffering salts and functional co-ingredients.

A typical design approach might include:

- Primary pH setter: citric, lactic or phosphoric acid, depending on flavour profile and target pH.

- Buffering component: sodium or potassium citrate, lactate or phosphate to stabilise pH over shelf life.

- Functional booster: ascorbate for antioxidant effect, or lactate for antimicrobial contribution in meat systems.

- Flavour fine-tuning: small amounts of malic, tartaric or acetic acid to adjust attack, body and aftertaste.

The ratio between these components is optimised through pilot-scale trials, sensory panels and shelf-life studies. Proper blending can often reduce the total dosage of acidity regulators while improving stability and consumer acceptance.

8) Step-by-Step Selection Framework for R&D and Procurement

To move from ad-hoc decisions to a systematic strategy, it helps to formalise the selection process for any acidity regulator system. The following framework can be adapted for your own product portfolio.

8.1 Define Technical Targets

- Target pH range in finished product and after processing (heat, fermentation, drying).

- Microbiological hurdle concept (pH, water activity, heat treatment, packaging).

- Sensory expectations: type and intensity of sourness; masking of off-notes.

- Texture and protein behaviour constraints (e.g. dairy and meat isoelectric points).

8.2 Screen Suitable Acidity Regulator Families

Based on the targets above, narrow down the families that are technically appropriate:

- Citrates for general purpose pH control and cost efficiency.

- Lactates for mild sourness, dairy compatibility and meat antimicrobial support.

- Malates for long-lasting sourness in fruit or reduced-sugar systems.

- Ascorbates where antioxidant and colour protection are critical.

- Phosphates, carbonates and bicarbonates for specific functional roles.

8.3 Check Regulatory and Labelling Fit

Confirm that each candidate meets regulatory requirements in all target markets and that the labelling is consistent with your brand positioning (e.g. classic vs clean-label).

8.4 Run Bench and Pilot Trials

Evaluate shortlisted systems in:

- Bench-top prototypes to compare pH curves, titratable acidity and sensory profile.

- Pilot plant trials to assess process robustness and interactions with other ingredients.

- Accelerated and real-time shelf-life studies to track pH stability, colour and flavour changes.

8.5 Optimise Cost-in-Use and Supply Security

Finally, review:

- Total cost per tonne of finished product, not just price per kilogram of additive.

- Supplier reliability, geographic diversification and port warehouse coverage.

- Options for standard vs customised blends to support different plants or product lines.

9) Conclusion: From Single Acid Choice to Acidity Strategy

Choosing an acidity regulator is no longer a simple question of “citric vs lactic acid”. As food systems become more complex and consumer expectations rise, pH control must be integrated with flavour design, texture, shelf life and labelling strategy.

Organic acids and their salts—especially citrates, lactates, malates and ascorbates—form the backbone of most solutions, with inorganic systems playing targeted roles. Citric acid remains the most widely used and cost-effective choice, but blended systems tailored to specific applications can deliver superior results and lower total cost in use.

By following a structured selection framework, checking regulatory compliance and working closely with experienced ingredient partners, food manufacturers can transform acidity regulation from a narrow technical adjustment into a powerful tool for product performance and brand differentiation.

GJ Phosphate is ready to support your projects—from choosing a single acidity regulator to designing full functional blends for beverages, bakery, meat, poultry and convenience foods.