If you are sourcing citric acid (E330) for food manufacturing, the fastest route to smooth approval

is aligning grade, key specs, granulation, documentation (COA/SDS/TDS), and export compliance

before you request pricing. This guide is written for procurement and QA teams who want fewer delays and more reliable

supplier comparisons.

Procurement tip: include grade, granulation, annual volume, and destination port in your first message to receive a faster, more accurate offer.

What you will learn

- Which grade to specify (food vs pharma vs technical)

- The spec items that most often decide QA approval

- How to select mesh/granulation for your process

- Which documents buyers typically request (COA/SDS/TDS and statements)

- Packaging & logistics points that prevent shipment delays

1) Grades & Typical Use Cases

“Citric acid” can be supplied in multiple grades. For B2B sourcing, the grade determines the

test package, impurity expectations, documentation depth, and in many cases the commercial terms.

Always state your target grade clearly in your inquiry.

Common supply grades

- Food Grade (E330): for foods and beverages as an acidulant/acidity regulator.

- Pharmaceutical (USP/EP where applicable): for pharma applications requiring pharmacopeia-aligned documentation.

- Technical/Industrial grade: for non-food applications (cleaning/descaling, industrial processes).

typical COA and a site-level documentation set early in qualification.

2) Key Parameters That Drive QA Approval (and Rejections)

Pricing is easy to compare. Specifications are where orders get delayed. The following items are the usual “gatekeepers”

in QA approval workflows for citric acid (E330).

High-impact specification items

- Assay / purity: define your minimum acceptable value.

- Moisture / loss on drying: influences caking, flowability, and storage stability.

- Sulfated ash: used as an indicator of inorganic residue/purity.

- Heavy metals (and lead): many buyers require both total heavy metals and a specific lead limit.

- Clarity/color/odor (when tested): particularly important for beverage applications.

but the order can stall once the COA does not match your internal/customer thresholds.

How to phrase your spec request

Ask for “standard COA limits + a typical COA” and confirm whether they can match your customer’s limits

for assay, moisture, sulfated ash, total heavy metals and lead.

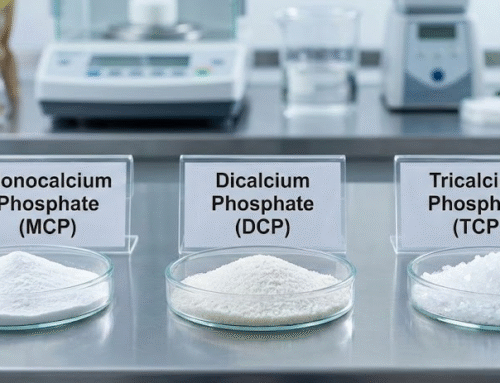

3) Mesh / Granulation: Match Particle Size to Your Process

Granulation affects dissolution speed, dusting, conveying, mixing uniformity, and batch-to-batch processing stability.

If your product quality depends on consistent dissolution, treat mesh/granulation as a controlled parameter.

Practical selection guidance

- Fine powder: fast dissolution; may increase dust. Best with good dust control.

- Granular/regular: better flowability and lower dusting; common for general food manufacturing.

- Coarse granules: helps reduce dust; may be preferred for certain handling systems.

mesh distribution definition on the TDS to avoid ambiguity.

4) COA & Documentation Checklist (What Buyers Typically Request)

A reliable supplier will support your approval process with consistent documents and clear batch traceability.

Below is a practical checklist used by procurement and QA teams during qualification and routine purchasing.

| Document | What to check | Why it matters |

|---|---|---|

| COA (Certificate of Analysis) | Lot/batch number, results vs limits, date, traceability to shipment docs | Determines release; protects you in audits and claims |

| SDS (Safety Data Sheet) | GHS classification, handling/storage, transport info | Required for workplace safety and warehouse onboarding |

| TDS (Technical Data Sheet) | Grade statement, standard limits, granulation options, shelf life, packaging | Prevents spec drift between quote and delivery |

| Allergen statement | Allergen status and cross-contact controls (as applicable) | Needed for customer declarations and audits |

| GMO statement | GMO status and basis | Frequently requested by brand customers/retail supply chains |

Often requested (market/customer dependent)

- Halal / Kosher certificates (if your market/customer requires)

- Certificate of Origin (for customs or customer documentation)

- Third-party inspection (e.g., SGS) when required contractually

5) Compliance Notes (EU / FDA / Codex)

Many international buyers reference common regulatory frameworks in internal approvals and customer documentation:

EU additive identification (E330), US FDA recognition, and Codex listings for international trade.

Your supplier should be able to support these references with clear grade statements and traceable COAs.

(1) the ingredient is recognized in the target framework, (2) the supplier provides supporting documents,

and (3) the delivered material meets your spec and your customer’s limits.

What to request from suppliers to support compliance statements

- Written grade statement (e.g., “Food grade citric acid (E330)”) on the TDS

- Batch traceability (lot number mapping to COA and packing list)

- Change control: notification before spec/process/site changes

6) Packaging & Logistics: Confirm These to Protect Lead Time

Even if the product meets spec, shipments can be delayed by packaging mismatches, missing documents,

or unclear commercial terms. Confirm these items up front to make your order warehouse-ready and customs-ready.

Packaging checklist

- Pack size: confirm standard (commonly 25 kg) and whether inner liner/moisture barrier is used.

- Palletization: confirm pallet type and wrapping; align with your warehouse requirements.

- Shelf life & storage: confirm shelf life on the TDS/COA and the recommended storage conditions.

Shipping & documentation checklist

- Incoterms & destination port: specify clearly for comparable quotes.

- Lead time definition: clarify whether it starts from PO confirmation or payment receipt.

- Document set: invoice, packing list, COA, SDS, certificate of origin (if required), certificates (if required).

7) What to Include in Your Inquiry (RFQ Checklist)

To receive faster quotes and avoid technical follow-up, include these items in your first message.

This also makes supplier offers comparable and easier to approve internally.

- Product: Citric Acid (E330), target grade (food/pharma/technical)

- Target specs: assay/purity minimum; moisture, sulfated ash, heavy metals and lead limits

- Granulation: fine / granular / coarse (request mesh definition on TDS)

- Volume: trial quantity + annual demand estimate

- Destination: country and port (for logistics and required documents)

- Packaging: 25 kg bags / jumbo bags and pallet requirements

- Documents required: COA, SDS, TDS, allergen/GMO statements, certificates if needed

- Commercial terms: incoterms, payment terms, expected lead time

Contact us here.

FAQ

Is citric acid the same as E330?

E330 is the additive identification commonly used for citric acid in EU-style labeling contexts.

For sourcing, always specify grade and your target specification limits to avoid misunderstandings.

What should I request first when qualifying a supplier?

A typical COA and TDS. These show the supplier’s standard limits, available granulation options, and whether their

documentation package matches your QA and customer requirements.

Does granulation matter for food manufacturing?

Yes. Particle size affects dissolution, dusting, conveying, and mixing performance. If your process is sensitive,

control granulation as a critical parameter and require change notification.