1) Overview: Moisture Loss and Yield Challenges in Frozen Shrimp

Frozen shrimp is one of the most widely traded seafood products in the global market, but it is also one of the most sensitive to moisture loss. Even small reductions in retained water can translate into significant yield loss, lower profitability, and customer complaints. For processors, controlling moisture is not simply a quality issue—it is a core economic concern.

A properly designed phosphate blend for frozen shrimp has become an industry-standard solution to address these challenges. Unlike basic single-salt treatments, phosphate blends allow processors to improve water uptake, stabilize texture, and reduce thaw loss in a controlled and compliant way.

2) Why Frozen Shrimp Loses Moisture During Processing

Shrimp muscle has a high natural moisture content but relatively weak structural integrity. Compared with meat or poultry, shrimp contains less connective tissue and fewer salt-soluble proteins, making it highly vulnerable to freezing and thawing stress.

Moisture loss typically occurs at multiple stages:

- Freezing: Ice crystals form inside muscle fibers, damaging cell membranes.

- Cold storage: Long storage times can lead to dehydration and protein denaturation.

- Thawing: Damaged muscle releases bound water as visible drip loss.

- Cooking: Heat further contracts proteins, expelling additional moisture.

Without functional intervention, these processes result in reduced net weight, poor appearance, surface whitening, and dry or rubbery texture after cooking.

3) Why Single Phosphates Are Not Enough

Traditional phosphates such as STPP have long been used in shrimp processing, but relying on a single phosphate compound often produces inconsistent results. This is because moisture retention in shrimp is influenced by multiple interacting factors, not a single chemical reaction.

Limitations of single phosphates include:

- Limited pH buffering range

- Uneven dissolution in cold soaking water

- Sensitivity to processing time and temperature

- Reduced effectiveness across different shrimp species and sizes

As processing systems become more standardized and export markets more demanding, processors increasingly require multi-functional solutions. This is why the industry has moved toward phosphate blends for frozen shrimp rather than single-salt applications.

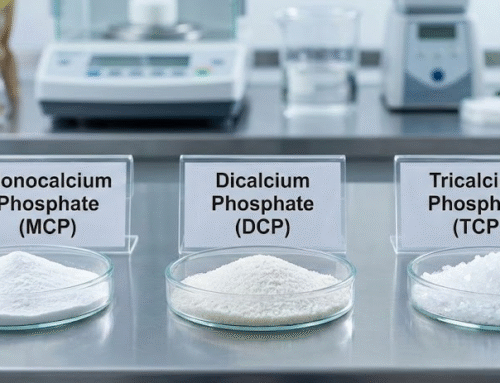

4) What Is a Phosphate Blend for Frozen Shrimp?

A phosphate blend is a carefully balanced combination of different food-grade phosphates designed to work synergistically. Instead of relying on one mechanism, blended phosphates provide multiple layers of functionality.

A well-formulated phosphate blend focuses on:

- Stable pH adjustment and buffering

- Improved protein-water interaction

- Effective metal ion chelation

- Fast and uniform dissolution in cold water

- Enhanced freeze–thaw stability

This multi-functional approach allows processors to achieve more consistent water uptake and lower thaw loss while maintaining product integrity.

5) How Phosphate Blends Increase the Weight of Frozen Shrimp

The controlled increase in shrimp weight comes from improved water retention rather than superficial water addition. Phosphate blends work at the protein level to stabilize moisture within the muscle structure.

5.1 Protein Charge and Structure Modification

Phosphates increase the net negative charge on muscle proteins, causing repulsion between filaments. This opens the protein network and creates space for water molecules to be retained.

5.2 Stronger Water Binding

Blended phosphates help convert loosely held water into more tightly bound water, reducing the amount of free water that escapes during thawing.

5.3 Practical Yield Results

Under optimized processing conditions, a suitable phosphate blend for frozen shrimp can typically deliver:

- Water uptake of 15–25%

- Thaw loss controlled at ≤5%

- Improved cooked yield and juiciness

6) Reducing Thaw Loss and Drip Loss in Frozen Shrimp

Thaw loss is one of the most visible quality indicators for buyers and end customers. Excessive drip creates a perception of poor quality and reduces saleable weight.

Phosphate blends reduce thaw loss by stabilizing protein-water interactions throughout frozen storage and thawing. Compared with single phosphate treatments, blends deliver more uniform moisture distribution and better batch-to-batch consistency.

7) Application of Phosphate Blend in Frozen Shrimp Processing

Phosphate blends are most commonly applied during the soaking or pre-treatment stage of frozen shrimp processing.

Key application considerations include:

- Effective performance in cold water (0–4°C)

- Controlled soaking time to avoid over-treatment

- Accurate concentration control

In practice, phosphate blends are often used alongside other food additives for seafood processing to optimize moisture retention, texture, and appearance.

8) Key Processing Variables Affecting Performance

The performance of a phosphate blend depends not only on formulation but also on processing conditions.

- Water temperature: Cold water requires fast-dissolving blends.

- Shrimp size: Smaller shrimp absorb water faster but are more sensitive to over-treatment.

- Soaking ratio: Water-to-shrimp ratio affects uptake efficiency.

- Freezing speed: Rapid freezing reduces structural damage and improves retention.

Understanding and controlling these variables is essential for achieving consistent results.

9) Regulatory and Export Compliance Considerations

Phosphate usage in frozen shrimp is regulated in most export markets. Regulations typically control total phosphate content rather than individual phosphate types.

Processors should reference international standards such as the Codex Alimentarius GSFA when developing compliant formulations. Industry-level guidance on seafood processing additives can also be found through organizations such as the SeafoodSource industry platform.

From a compliance perspective, phosphate blends often allow lower total dosage while achieving the same or better functional results.

10) How to Choose the Right Phosphate Blend

When selecting a phosphate blend for frozen shrimp, buyers should evaluate:

- Dissolution speed in cold water

- Consistency across shrimp species and sizes

- Effectiveness in reducing thaw loss

- Impact on texture and appearance

- Technical support and export compliance guidance

The objective is not to maximize chemical strength but to achieve stable, repeatable processing performance.

Conclusion

Moisture loss and yield reduction are unavoidable risks in frozen shrimp processing, but they can be effectively managed with the right functional strategy. A properly designed phosphate blend for frozen shrimp offers a balanced and compliant approach to increasing water uptake, reducing thaw loss, and stabilizing product quality.

By addressing protein structure, water binding, and freeze–thaw stability simultaneously, phosphate blends transform phosphates from basic additives into precision processing tools. For processors focused on yield, consistency, and export readiness, choosing the right phosphate blend is a strategic decision with long-term impact.