Food grade monocalcium phosphate (MCP), also recognized under the European food additive code E341(i), is a vital inorganic compound widely used in the global food industry. As a leavening agent, buffering agent, and calcium source, it ensures product stability, texture, and nutritional value in countless applications ranging from bakery to dairy. This article explores the science, manufacturing, regulatory standards, and market dynamics behind food grade MCP—and how GJ Phosphate ensures consistent supply for international customers.

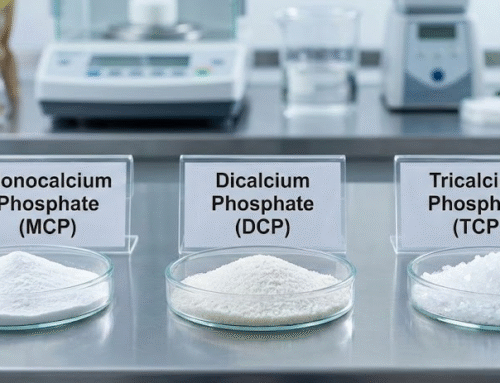

1. What Is Food Grade Monocalcium Phosphate?

Food grade MCP is a white, odorless, free-flowing crystalline powder composed primarily of Ca(H₂PO₄)₂. It contains approximately 22% phosphorus and 15% calcium, making it a valuable nutritional additive and a functional ingredient in food formulations. In the food industry, it is used both for its chemical properties—such as buffering and leavening—and for its contribution to calcium enrichment in processed foods.

Classified internationally as E341(i), monocalcium phosphate is a permitted additive under global regulations including FCC, EU Regulation (EC) No 1333/2008, Codex Alimentarius, and GB 1886.334-2021 in China. It is recognized as safe when produced under strict purity and heavy metal limits.

2. Chemical Composition and Manufacturing Process

The production of food grade monocalcium phosphate involves the controlled reaction of phosphoric acid (H₃PO₄) with high-purity calcium carbonate (CaCO₃). The process is designed to maintain chemical stoichiometry, avoid impurities, and ensure precise particle morphology.

Key Manufacturing Steps

- Reaction: CaCO₃ + 2H₃PO₄ → Ca(H₂PO₄)₂ + CO₂↑ + H₂O

- Filtration & Purification: Removal of insoluble residues and trace metals.

- Crystallization: Controlled cooling to form uniform crystalline particles.

- Drying & Milling: Moisture removal and particle-size adjustment for specific applications.

The resulting product must meet tight specifications: P₂O₅ content ≥ 51%, loss on drying ≤ 2%, heavy metals ≤ 10 ppm. Analytical methods include ICP-OES, XRD, and laser particle-size analysis to guarantee batch consistency.

3. Functional Roles in the Food Industry

Food grade MCP serves multiple roles across food manufacturing sectors, making it a multifunctional additive for formulators and food technologists.

3.1 Leavening Agent in Baking

MCP is an essential acid source in baking powders. When combined with sodium bicarbonate, it reacts to release carbon dioxide, ensuring even dough rise and optimal crumb texture. Its balanced reactivity rate allows for consistent leavening during mixing and baking stages.

3.2 pH Regulator and Buffer

MCP maintains stable acidity in foods like dairy, beverages, and sauces. As a buffering agent, it prevents undesirable pH drift, protecting flavor and color integrity.

3.3 Mineral Source

Owing to its high bioavailability, MCP contributes to calcium and phosphorus fortification in nutritional beverages, powdered mixes, and dietary supplements.

3.4 Stabilizer and Texture Enhancer

In meat and processed foods, MCP improves texture, water retention, and emulsification, working synergistically with other phosphates such as sodium tripolyphosphate (STPP) and tetrasodium pyrophosphate (TSPP).

4. Quality Standards and Compliance

Food grade MCP must comply with international standards, ensuring purity and safety. Key benchmarks include:

- FCC (Food Chemicals Codex): Defines chemical identity, solubility, and impurity limits.

- EU E341(i): Authorizes MCP as a food additive with specified purity and usage categories.

- GB and ISO Standards: Compliance with China GB 1886.334 and ISO 22000 food safety management.

- Certifications: HACCP, Halal, Kosher, and ISO 9001.

GJ Phosphate’s production facilities operate under ISO and GMP frameworks to ensure traceability and batch uniformity, supporting global customers with full documentation (CoA, TDS, SDS, and compliance certificates).

5. Packaging, Handling, and Shelf Life

Food grade MCP is typically packaged in 25 kg multi-layer paper or polyethylene bags with inner liners to protect against moisture. Bulk packaging in 500 kg or 1000 kg jumbo bags is available for industrial customers.

It should be stored in a dry, ventilated warehouse, away from volatile chemicals and humidity. Under proper conditions, shelf life can exceed 24 months.

6. Global Market Overview

The global food phosphate market continues to grow steadily, driven by bakery expansion, convenience foods, and fortification trends. Food grade MCP represents a critical segment thanks to its dual nutritional and functional value.

Key Demand Regions

- Asia-Pacific: Leading demand due to bakery and dairy industries in China, India, and Southeast Asia.

- Europe: Stable demand under strict E-number compliance; focus on natural and clean-label additives.

- North America: High adoption in baking mixes, processed meats, and ready-to-eat foods.

Price stability depends on phosphoric acid costs, transportation, and energy inputs. Reliable phosphate suppliers like GJ Phosphate mitigate volatility through integrated production and forward logistics planning.

7. Food Grade vs Feed Grade MCP

Though chemically similar, food and feed grade monocalcium phosphate differ in purity, particle control, and certification requirements.

| Parameter | Food Grade MCP | Feed Grade MCP |

|---|---|---|

| Purity Level | High; meets FCC/EU E341(i) | Moderate; meets feed additive specs |

| Heavy Metals (Pb, As, Cd) | <10 ppm total | <30 ppm total |

| Applications | Food, baking, dairy, beverages | Animal nutrition, feed premix |

| Regulatory Framework | Food additive legislation | Feed additive (FAMI-QS or GMP+) |

| Packaging | Moisture-proof food-grade liner | Standard industrial bags |

Food manufacturers must ensure MCP suppliers provide the correct grade and documentation to prevent cross-contamination or labeling non-compliance.

8. Why Choose GJ Phosphate

As a global phosphate exporter, GJ Phosphate supplies food-grade monocalcium phosphate with certified quality, consistent particle distribution, and guaranteed traceability. Our integrated production covers raw phosphoric acid to finished MCP, minimizing variability and ensuring reliable delivery.

- ISO 9001 and ISO 22000 certified production

- Batch-level traceability and digital documentation

- Flexible packaging (25 kg, 500 kg, 1000 kg)

Explore Food Grade Phosphates

Contact Our Food Additive Team

9. FAQ

Q1: Is food grade monocalcium phosphate safe?

Yes. It is approved by major food authorities (FDA, EFSA, CFSA) as E341(i) and considered safe within regulated dosage levels.

Q2: What is the difference between E341(i) and E341(ii)?

E341(i) refers to monocalcium phosphate, while E341(ii) represents dicalcium phosphate—each has different solubility and reactivity for specific applications.

Q3: How is MCP used in baking powder?

MCP reacts with sodium bicarbonate to release CO₂, allowing dough to rise evenly. Its moderate reaction rate ensures controlled leavening during baking.

Q4: Can the same MCP be used for both food and feed?

No. Feed-grade MCP does not meet food purity requirements. Only food-grade material should be used in edible applications.

Q5: What documents are provided by GJ Phosphate?

Customers receive CoA, TDS, SDS, food safety declarations (Halal, Kosher), and packaging information with each batch.