Using phosphates as water retention agents is one of the most efficient and reliable ways to improve yield, juiciness, and texture in meat, seafood, dairy, bakery and convenience foods.

For R&D, QA and procurement teams, understanding how phosphates enhance water holding capacity is critical for designing cost-effective, high-quality products that comply with global regulations.

1) Introduction: Why Use Phosphates as Water Retention Agents?

In modern food processing, water holding capacity (WHC) is a central performance parameter. It directly influences:

- Cooked yield and economic efficiency.

- Texture, juiciness, and mouthfeel.

- Slice integrity and processing stability.

- Drip loss during storage, thawing, and distribution.

For decades, formulators have relied on phosphates as water retention agents because they offer a powerful combination of:

- Proven technological effect (higher yield, better texture).

- Low use levels with strong functional impact.

- Well-established regulatory frameworks in most markets.

- Compatibility with salt, proteins, hydrocolloids and other ingredients.

In properly designed systems, phosphates do not simply “add water”, they unlock the protein’s natural capacity to bind and retain moisture under processing stress.

2) Mechanism: How Phosphates Improve Water Holding Capacity

Different phosphate types (orthophosphates, pyrophosphates, polyphosphates) act through complementary mechanisms at the protein and water interface.

The main mechanisms include:

2.1 Protein Structure Modification

In meat and seafood, muscle proteins (especially myofibrillar proteins) govern water binding. Polyphosphates can:

- Increase the net negative charge on proteins.

- Promote protein unfolding, exposing more binding sites.

- Enhance solubility of salt-soluble proteins.

This structural modification allows the protein network to incorporate and retain more water, especially during heating or freezing–thawing cycles.

2.2 Chelation of Divalent Ions

Calcium (Ca²⁺) and magnesium (Mg²⁺) can tighten protein structures and reduce solubility. Phosphates chelate these ions, mitigating their tightening effect and improving protein functionality.

This chelation also helps prevent unwanted precipitation in dairy and beverage systems, contributing indirectly to water retention and stability.

2.3 pH Adjustment & Buffering

Proteins exhibit minimal water binding at their isoelectric point (pI). By slightly increasing pH away from the pI, phosphates:

- Increase electrostatic repulsion between protein chains.

- Open up the protein matrix for water and fat emulsion.

- Enhance WHC and reduce cooking loss.

2.4 Synergy with Salt & Other Ingredients

In many formulations, phosphates are used with:

- Sodium chloride (NaCl): to extract salt-soluble proteins.

- Proteins (e.g., soy, milk, plasma): for binding and emulsion stability.

- Hydrocolloids (e.g., carrageenan, gums): for water immobilization.

The result is a multi-level water retention system: chemically bound water (proteins + phosphates), physically entrapped water (gels), and emulsified water (in oil–water systems).

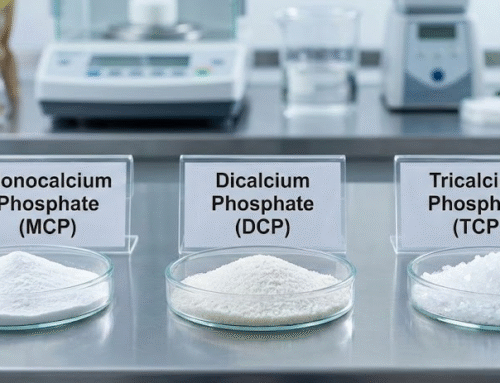

3) Key Phosphate Types for Water Retention

Not all phosphates perform equally as water retention agents. The most commonly used food-grade phosphates include:

| Phosphate | Typical Abbreviation | Functional Highlights | Common Applications |

|---|---|---|---|

| Sodium Tripolyphosphate | STPP | Strong water binding, pH increase, chelation | Meat, poultry, seafood, frozen products |

| Tetrasodium Pyrophosphate | TSPP | Protein reactivity, texture and elasticity | Meat products, surimi, processed cheese |

| Sodium Acid Pyrophosphate | SAPP | Controlled reactivity, leavening acid, texture | Bakery, fried snacks, batter systems |

| Sodium Hexametaphosphate | SHMP | Strong chelation, sequestering agent | Dairy, beverages, sauces, seafood glazing |

| Mixed Phosphate Blends | STPP+TSPP+SHMP etc. | Balanced water retention, texture, shelf life | Complex meat systems, ready meals |

Formulation tip: Many commercial solutions use custom phosphate blends to fine-tune water retention, protein functionality, and processing behavior in specific products.

4) Meat & Poultry Applications

The meat and poultry industry remains the biggest user of phosphates as water retention agents. From whole muscle cuts to emulsified sausages, STPP and related phosphates are critical for yield and quality.

4.1 Injected & Tumbled Meat

In injected or tumbled products (chicken breast, hams, cooked turkey, marinated pork), phosphates are typically included in:

- Brines for injection or pumping.

- Marinades for tumbling/massaging.

- Dry rubs for certain applications.

Benefits include:

- Increased raw and cooked yields (often +5–12% depending on system).

- Improved sliceability and reduced crumbling.

- Enhanced juiciness and tenderness perception.

- Better freeze–thaw stability in frozen products.

4.2 Emulsified & Restructured Meat Products

In frankfurters, bologna, luncheon meat, nuggets, and reformed products, phosphates:

- Help extract and solubilize myofibrillar proteins for stable emulsions.

- Improve fat and water binding to reduce syneresis and jelly exudate.

- Contribute to a firm, elastic, and uniform bite.

4.3 Clean Label Perspectives

In some markets, there is pressure to reduce or remove phosphates in “clean label” concepts. Manufacturers may:

- Reduce phosphate dosage while combining with proteins or fibers.

- Shift to naturally derived functionality enhancers but often at higher cost.

- Maintain phosphates for higher-yield product lines and offer “no phosphate” premium options in parallel.

For mainstream, value-focused and export-oriented products, phosphates remain difficult to replace entirely due to their strong and cost-effective impact on water retention.

5) Seafood & Aquatic Products

In seafood, phosphates are mainly applied to shrimp, fish fillets, squid, scallops, and surimi-based products. Water loss during freezing and thawing is a major issue in this category, directly impacting weight, appearance, and texture.

5.1 Shrimp & Fish Fillets

Soaking or tumbling in brines containing STPP and/or SHMP helps:

- Reduce drip loss during thawing.

- Maintain plump appearance and bite.

- Protect proteins from denaturation during frozen storage.

5.2 Surimi & Seafood Analogues

In surimi and restructured seafood:

- TKP, TSPP and blends contribute to gel strength and elasticity.

- Phosphates interact with myofibrillar proteins to create cohesive textures.

- Water retention supports juicy bite and reduces syneresis in ready-to-eat formats.

As with meat, dosage and brine conditions must be optimized to avoid excess surface moisture or texture defects.

6) Bakery & Cereal Products

In bakery, phosphates are more widely known as leavening acids, but they also contribute to moisture management, texture and shelf life.

6.1 Leavening Systems

Phosphates such as SAPP, MCP and DCP are used in baking powders to release carbon dioxide in combination with sodium bicarbonate. While their primary role is gas generation, secondary impacts include:

- Control of batter pH and viscosity.

- Crumb structure and volume.

- Retention of moisture in cakes and muffins over shelf life.

6.2 Frozen & Par-Baked Dough

In frozen dough and par-baked products, phosphates can:

- Help maintain dough strength and stability.

- Reduce freeze–thaw damage to gluten network.

- Support consistent volume and soft texture after final baking.

Here, phosphates act in synergy with enzymes, emulsifiers, and hydrocolloids that further control water mobility and staling.

7) Dairy, Cheese & Processed Foods

In dairy and cheese systems, phosphates may not be labeled as “water retention agents”, but their functional role often includes moisture control and stability.

7.1 Processed Cheese & Cheese Sauces

Polyphosphates (TSPP, STPP, SHMP) are used as emulsifying salts to:

- Solubilize and disperse casein.

- Bind calcium and prevent protein aggregation.

- Create a stable oil-in-water emulsion with uniform texture.

This leads to improved meltability, sliceability, and reduced oil separation, which are closely related to how water is distributed and retained in the matrix.

7.2 Dairy Beverages & Powdered Products

In flavored milks, dairy beverages and powders, phosphates:

- Help maintain mineral balance and prevent sedimentation.

- Support dispersion of proteins for smooth mouthfeel.

- Stabilize systems during UHT processing and storage.

Good mineral and protein dispersion ultimately supports stable water distribution, reducing phase separation and textural defects.

8) Formulation Guidelines & Practical Dosage Ranges

When using phosphates as water retention agents, dosage must be optimized for efficacy, sensory quality, and regulatory compliance.

8.1 Typical Use Levels

| Application | Phosphate Type | Typical Use Level (Indicative) | Notes |

|---|---|---|---|

| Injected / tumbled meat | STPP / blends | 0.2 – 0.5% in finished product | Higher brine levels; respect local regulations. |

| Emulsified sausages | STPP + TSPP | 0.3 – 0.6% | Optimize with salt and proteins. |

| Shrimp / seafood soaking | STPP / SHMP | Brine typically 3–8% phosphate | Control soaking time and temperature. |

| Processed cheese | TSPP / STPP / SHMP blends | 1 – 3% of cheese mass | Depends on cheese type and process. |

| Bakery (leavening) | SAPP / MCP / DCP | According to baking powder design | Focus primarily on gas release profile. |

Values above are indicative and must be adapted to local regulations, specific formulations, and process conditions. Pilot trials are essential.

8.2 Good Formulation Practices

- Use high-quality, food-grade phosphates from reputable suppliers.

- Control mixing order—typically dissolve phosphates in water before adding proteins or other solids.

- Monitor pH to avoid excessive alkalinity that may affect flavor or texture.

- Balance phosphates with salt, proteins, and hydrocolloids for synergistic effects.

- Conduct yield, texture, and sensory tests across multiple batches.

9) Regulatory, Labeling & Consumer Considerations

Phosphates are widely approved food additives, but usage levels and permitted categories vary by region. They are generally labeled with their specific names or E-numbers (e.g., E450, E451, E452).

Key points for regulatory and consumer alignment:

- Verify local maximum usage levels and target product categories.

- Ensure cumulative phosphate intake stays within dietary recommendations.

- Consider consumer perception: some segments seek “reduced additive” or “clean label” solutions.

- Where needed, communicate the functional benefits of phosphates (quality, safety, food waste reduction).

Many brands now segment their portfolios: some lines maintain classical phosphate-based formulas for maximum yield and stability, while others explore phosphate alternatives for niche markets.

10) Sourcing Strategy: Choosing a Phosphate Supplier

For manufacturers, the choice of phosphate supplier directly affects product consistency, regulatory compliance, and cost management. A strong partner provides more than commodity powders.

What to Look For

- Proven experience in food-grade phosphates.

- ISO, HACCP, and food safety certifications.

- Detailed CoA and TDS, including functional data where relevant.

- Flexible packaging and logistics solutions for your region.

Questions to Ask

- Can you support trials with different phosphate blends?

- How do you control heavy metals, fluorides, and impurities?

- What change-control and notification processes do you follow?

- Do you support technical visits, audits, and long-term contracts?

A strategic phosphate supplier becomes part of the innovation and cost-optimization process, not just a commodity vendor.

11) How GJ Phosphate Supports Water Retention Programs

GJ Phosphate offers a comprehensive portfolio of food grade phosphates designed for water retention, texture improvement, and process stability in meat, seafood, dairy, bakery and convenience foods.

| Product Type | Typical Role in Water Retention | Key Target Applications |

|---|---|---|

| Sodium Tripolyphosphate (STPP) | Strong water binding and yield improvement | Meat and seafood brines, tumbled products |

| Tetrasodium Pyrophosphate (TSPP) | Texture, protein reactivity, elasticity | Processed meat, surimi, cheese systems |

| Sodium Hexametaphosphate (SHMP) | Chelation, stability, reduced drip | Seafood, dairy beverages, sauces |

| Phosphate Blends | Balanced WHC, pH, and functionality | Complex meat and ready-meal formulations |

Our technical and commercial teams support:

- Selection of the right phosphate system for your product.

- Trial design and evaluation of yield, WHC and texture.

- Regulatory and documentation alignment for export markets.

- Long-term supply planning and logistics coordination.

12) FAQ: Phosphates as Water Retention Agents

Q1: Are phosphates safe to use as water retention agents in foods?

Yes. Food-grade phosphates are approved by major regulatory authorities when used within specified limits. They have been used for decades to improve quality, safety, and yield in processed foods.

Q2: Do phosphates simply add water to products?

Phosphates influence the protein and mineral balance so that the product can naturally hold more water during processing. When correctly used within regulations, they improve juiciness and yield without creating “waterlogged” or defective textures.

Q3: Can we replace phosphates with “clean label” alternatives?

Some alternatives (proteins, fibers, hydrocolloids, fermented ingredients) can partially replace the functional role of phosphates, but often at higher cost and with more complex processing. Many manufacturers balance traditional phosphate-based lines with selected “no phosphate” items.

Q4: Which phosphate should I start with for meat water retention?

Sodium tripolyphosphate (STPP) is a common starting point due to its strong water binding effect. However, the optimal system may combine STPP with other phosphates. Pilot trials are essential.

Q5: How can GJ Phosphate help?

GJ Phosphate supplies a range of food-grade phosphates and blends, and works with customers to tailor specifications, support application trials, and ensure consistent, compliant supply for long-term programs.

Disclaimer: This article is for technical and commercial guidance only. Always confirm local regulations, nutritional recommendations, and product specifications before finalizing formulations or labels.