On specification sheets, both products may simply be described as “Sodium Tripolyphosphate (STPP, E451(i))”. But in real food plants, fast soluble STPP and normal food grade STPP behave very differently – especially in cold-water brines and high-speed processing lines.

This guide explains the functional role of STPP in food, how bulk density and particle structure determine dissolution speed, and how purchasing managers can choose the right type of STPP for meat, seafood, dairy, beverages and instant products.

1) The Role of STPP in Food Applications

Sodium tripolyphosphate (STPP) is one of the most widely used food-grade phosphates. In meat, seafood, dairy and many processed foods, STPP is a key functional ingredient rather than a simple “additives”. It contributes to:

- Water binding and yield: STPP increases the water-holding capacity of proteins, reducing cooking loss and purge.

- Texture and juiciness: Proper use of STPP helps create a tender, juicy bite in meat and seafood products.

- Protein functionality: It improves protein solubility and extraction, especially in combination with salt.

- Stabilisation of emulsions: In sausages and processed cheeses, STPP helps stabilise fat-in-water systems.

- pH and buffering: STPP slightly increases pH, moving proteins away from their isoelectric point and improving water binding.

Regulatory bodies including FAO/WHO JECFA, EFSA and the US FDA have evaluated the safety of STPP as a food additive when used within specified limits and good manufacturing practice. For buyers, this means the key question is not “Is STPP allowed?” but rather “Which STPP grade and type is technically correct for my application?”

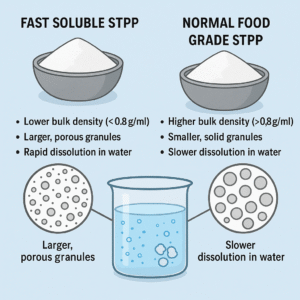

2) Bulk Density, Particle Structure and Dissolution Speed

In practice, “fast soluble STPP” refers mainly to differences in bulk density and particle morphology rather than a different chemical composition. Both fast soluble and normal STPP share the same chemical formula (Na5P3O10) and are typically manufactured from the same raw materials.

What changes is the physical structure created by the production process:

2.1 High-Density STPP (> 0.8 g/ml)

High-density food-grade STPP is usually produced by spray-drying a melt into small, compact, almost spherical particles. These particles:

- pack closely with limited void space between them,

- have relatively low porosity,

- are physically small but heavy per unit volume,

- show bulk densities typically above 0.8 g/ml.

For logistics, this is attractive: more STPP can fit into a bag, a pallet, or a shipping container. For formulation, the behaviour in water is very different from low-density material.

2.2 Low-Density STPP (< 0.8 g/ml)

Low-density STPP, often marketed as “fast soluble STPP” or “low-bulk-density STPP”, is commonly produced by dry (tower) polymerisation. This process creates:

- irregular, sponge-like particles with many internal pores,

- fluffy aggregates that trap air between particles,

- a larger apparent particle size but a much lower bulk density,

- bulk density values below 0.8 g/ml, sometimes in the 0.5–0.7 g/ml range.

Visually, low-density STPP looks more voluminous in the same bag size. For a given weight, it occupies more space, but it also interacts with water very differently.

3) Why Low-Density STPP Dissolves Faster

In many food factories, the practical question is simple: “Why does one STPP dissolve quickly in cold water, while another requires long mixing or forms stubborn lumps?”

The answer lies in three physical mechanisms.

3.1 Larger Effective Surface Area

The porous, fluffy structure of low-density STPP means that water can contact not only the outer surface of each particle, but also penetrate into the internal pores. From a dissolution perspective, the effective surface area is many times higher than that of compact, high-density granules.

More surface area in contact with water means the sodium tripolyphosphate molecules can move into solution much more quickly, especially in cold-water brines used for meat injection or seafood tumbling.

3.2 Better Wetting and Dispersion

High-density STPP, especially in fine powder form, tends to form clumps or “fish eyes” when added to water. The outer layer dissolves and forms a viscous shell, while the interior remains dry. These lumps then slowly break down under mechanical agitation.

Low-density, granular STPP is less prone to this behaviour. Its open structure:

- allows water to penetrate quickly,

- reduces the risk of surface crusting,

- disperses more evenly in the tank,

- greatly shortens total dissolution time.

3.3 Longer Residence Time in the Water Phase

Low-density particles settle more slowly due to their lower mass per unit volume. In practice, this means:

- they remain suspended and agitated for longer,

- they have more time to interact with water before reaching the tank bottom,

- overall mass transfer between solid and liquid is more efficient.

For brine systems where mixing time is limited – for example when preparing multiple batches per shift – this behaviour is a major advantage.

4) Fast Soluble STPP vs Normal Food Grade STPP

From a buyer’s perspective, it is useful to summarise the practical differences between fast soluble and normal food-grade STPP:

| Parameter | Fast Soluble / Low-Density STPP | Normal / High-Density Food Grade STPP |

|---|---|---|

| Bulk density | Typically < 0.8 g/ml (fluffy, porous) | Typically > 0.8 g/ml (compact, tightly packed) |

| Production route | Dry (tower) polymerisation, forming porous aggregates | Spray-drying of melted phosphate into solid spheres |

| Apparent particle size | Larger, irregular granules / aggregates | Smaller, regular spherical particles |

| Dissolution in cold water | Very fast, good wetting, minimal lumping | Slower, risk of “fish eyes” and agglomerates |

| Logistics efficiency | Lower weight per bag / pallet / container | Higher weight per volume, better freight utilisation |

| Typical use cases | Meat and seafood brines, dairy/protein drinks, bakery mixes, instant beverages | Applications where dissolution time is less critical; plants focused on logistics efficiency |

5) How Purchasing Managers Should Choose Food-Grade STPP

In many companies, STPP is still purchased as a commodity based mainly on price and general food-grade specifications. For plants where performance matters, a more structured approach is advisable.

5.1 Step 1 – Clarify the Application and Process

When sending inquiries to suppliers or manufactuer, always specify:

- the end application (e.g. injected poultry, surimi, processed cheese, UHT dairy drink, instant coffee),

- whether STPP is dissolved in cold or hot water,

- available mixing time and equipment (static tank, high-shear mixer, inline dissolver),

- any specific problems in current production (lumps, undissolved residues, long preparation times).

This information allows the supplier to recommend the appropriate bulk density and particle form.

5.2 Step 2 – Look Beyond Standard Specifications

Basic food-grade specifications (assay, pH, heavy metals, insolubles) are necessary but not sufficient. For performance-critical applications, buyers should also request:

- Clear statement of bulk density (e.g. 0.55–0.70 g/ml vs 0.85–0.95 g/ml),

- particle size distribution or typical particle size range,

- dissolution time data in specified conditions (for example, 10% solution in cold water at 10 °C).

Some suppliers can provide comparative dissolution curves for different STPP types, which is very useful during technical evaluation.

5.3 Step 3 – Match Density to Logistics and Application Needs

In practice, there is a trade-off between logistics efficiency and process performance:

- For plants where container loading and warehouse space are the primary constraints, high-density STPP may be more economical.

- For plants where cold-water dissolution and quick changeovers are critical (for example, meat brine mixing every batch), fast soluble STPP often offers a better total cost of ownership.

A pragmatic strategy is to use:

- high-density STPP in applications where it is simply added to a batch with long mixing time, and

- fast soluble, low-density STPP in sensitive, time-critical or cold-water applications.

5.4 Step 4 – Run Comparative Trials

Before switching large volumes, it is recommended to run side-by-side trials with:

- identical formulation and process parameters,

- normal vs fast soluble STPP at the same dosage (by weight),

- measurement of dissolution time, solution clarity, brine stability and final product quality (yield, texture, sensory).

Such trials often reveal that an apparently more expensive fast soluble STPP reduces labour, downtime and quality losses enough to be more economical overall.

6) Key Application Scenarios for Fast Soluble STPP

Fast soluble STPP is particularly valuable where cold-water dissolution, high solids content and short mixing times coincide. Below are typical application groups.

6.1 Meat Products – Cold Brine Injection and Tumbling

In injected or tumbled meat (poultry, pork, beef), STPP is usually dissolved in cold brine together with salt, sugar and sometimes proteins or hydrocolloids. Fast dissolution is critical because:

- brine temperature must be kept low to control microbiological risk and protein stability,

- multiple brine batches may be prepared per shift,

- undissolved particles can clog injectors or create uneven functional performance inside the meat.

Fast soluble, low-density STPP allows processors to achieve:

- rapid preparation of clear, homogeneous brines,

- less risk of “hot spots” with high local concentration,

- more consistent injection and tumbling results across batches.

6.2 Seafood – Soaking and Injection of Fish and Shrimp

In shrimp, fish fillets and other seafood, STPP is widely used as a water-binding and texture-improving agent. The typical operations involve soaking or injection with cold phosphate solutions.

Fast soluble STPP helps:

- prepare phosphate solutions quickly between production batches,

- avoid sediment that can accumulate in tanks and pipelines,

- ensure uniform treatment so that products have consistent appearance and yield.

6.3 Dairy, Protein Beverages and Plant-Based Drinks

In dairy-based and plant-based protein beverages, STPP may be used in combination with other phosphates and citrates to stabilise casein or plant proteins and adjust pH. When processing at low temperature and high throughput, undissolved particles are problematic.

Fast soluble STPP is suitable for:

- UHT dairy drinks and recombined milk,

- RTD protein beverages (whey, casein, plant protein),

- coffee creamers and whiteners.

6.4 Bakery and Instant Beverages

In bakery premixes and instant beverage powders, STPP may be used as a functional phosphate or process aid. When the mix is dissolved by the end consumer (for example instant coffee or beverage powders), dissolution speed becomes part of the user experience.

Using fast soluble STPP in premixes helps:

- avoid undissolved granules in the cup,

- improve clarity and mouthfeel,

- reduce complaints about “sediment” in instant products.

7) Regulatory Limits and Compliance Considerations

While the focus of this article is on functionality and purchasing decisions, it is essential to emphasise that STPP is a regulated food additive. Different countries and regions specify:

- which food categories may contain STPP,

- maximum permitted levels (often expressed as total phosphate or P2O5),

- labelling requirements (e.g. “E451(i)”, “sodium tripolyphosphate”, “phosphates”).

Buyers and formulators must always check local legal frameworks (Codex, EU, US, national standards) and ensure that:

- STPP is allowed in the specific food category,

- combined use of different phosphates does not exceed group limits,

- finished products remain compliant even after yield improvement.

For background, you may refer to evaluations by international and national authorities such as

JECFA (FAO/WHO) for INS 451(i),

EFSA’s re-evaluation of phosphates as food additives,

21 CFR §182.1810 Sodium tripolyphosphate.

Always consult your regulatory or quality department to confirm applicable limits before finalising specifications or formulations.

8) Evaluating STPP Suppliers: Questions Buyers Should Ask

Since fast soluble STPP and normal STPP can look similar on paper, supplier capability and transparency become critical. When evaluating offers, consider asking:

- Is the product explicitly food grade, and which standards does it follow (FCC, EU, GB, etc.)?

- What is the typical bulk density and its tolerance?

- Which process route is used (spray-dried vs dry polymerised)?

- Can the supplier provide dissolution time data in cold water?

- What are the limits for heavy metals, fluoride and insoluble matter?

- Is the production site audited for food safety (e.g. ISO, FSSC, HACCP)?

- Can they offer both normal and fast soluble STPP so you can benchmark options?

Working with a specialised phosphate supplier such as GJ Phosphate allows buyers to access multiple production sources while maintaining a consistent technical and quality interface. This is particularly valuable when you need to qualify different grades (high density vs low density) for different plants or product lines.

9) Summary: Matching STPP Type to Application and Process

For food manufacturers, choosing between fast soluble STPP and normal food-grade STPP is not just a price decision. It is a strategic choice that affects:

- brine preparation time and labour cost,

- risk of undissolved particles and equipment issues,

- yield, texture and consistency of meat, seafood, dairy and instant products,

- logistics efficiency and storage space utilisation.

High-density STPP offers better packing efficiency and is suitable where long mixing times and hot water are available. Low-density, fast soluble STPP is the better choice where cold-water dissolution, short batch cycles and high solids content are part of everyday reality.

By clearly communicating your application and process conditions to your supplier, requesting data on bulk density and dissolution speed, and running focused plant trials, purchasing managers can move from buying “generic STPP” to sourcing the right STPP for each product line.

If you are currently comparing different STPP grades or experiencing issues with dissolution, our technical team can help review your requirements and recommend suitable fast soluble or normal STPP solutions.