Dicalcium Phosphate (DCP) is a cornerstone inorganic phosphate across feed, food, and select pharma applications.

For B2B buyers in 2025, success hinges on matching grade and particle profile to the process, enforcing documentation discipline, and building a resilient, auditable supply program.

This guide translates technical detail into procurement action—authored by GJ Phosphate.

Request a Quote

1) Introduction: Why DCP Matters in 2025

Dicalcium Phosphate (commonly DCP) serves as a reliable, cost-effective source of calcium and phosphorus. Its dual role as a

nutritional fortifier and a functional processing aid stabilizes demand across multiple industries. In feed, DCP underpins animal growth, bone development,

and metabolic health. In food and pharma, controlled purity and particle engineering enable predictable performance in tablets, fortified foods, and processing aids.

For procurement teams, the critical variables are grade selection, particle-size distribution (PSD), documentation, and logistics reliability.

Executive Snapshot

- DCP demand remains structurally supported by feed and nutrition programs.

- Specification discipline (nutrient guarantees, impurities, PSD) determines cost-in-use.

- Documentation speed and change-control rigor are now RFP differentiators.

- Packaging, moisture control, and warehouse conditions shape real-world performance.

2) Chemistry & Core Characteristics

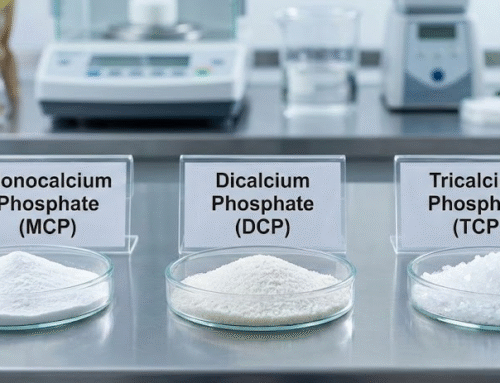

Dicalcium Phosphate is generally represented as CaHPO₄·2H₂O for the dihydrate, with anhydrous variants available for specific uses.

It appears as a white, odorless powder or granules, low in moisture when properly packed, and stable under standard storage conditions.

Functional attributes relevant to buyers include nutrient density (calcium & phosphorus), flowability, compression behavior for tablets, and compatibility with other ingredients.

Physical & Functional Traits

- White powder/granules; adjustable particle size for handling and dosing

- Stable under dry, ambient warehouse conditions

- Neutral taste; low reactivity in most food/feed matrices

- Good compressibility for direct-compression tablet systems (pharma/OTC)

Buyer-Relevant Parameters

- Guaranteed calcium and phosphorus percentages

- Impurities profile (heavy metals, fluoride as applicable)

- Moisture and loss on drying

- PSD and bulk density for hopper/screw feeders

3) Grades & Typical Specifications

DCP is commercialized in several grades aligned to end-use requirements. While exact numbers vary by supplier, the table below

illustrates typical specification snapshots. Buyers should always benchmark against the supplier’s CoA and TDS.

Feed Grade DCP

| Appearance | White/off-white powder or granules |

|---|---|

| Calcium (Ca) | Typical ≥ 22–24% (spec-dependent) |

| Phosphorus (P) | Typical ≥ 18–19% (spec-dependent) |

| Moisture | Controlled for caking and flow |

| Fluoride | Within feed-grade limits |

| Heavy Metals | Within feed-grade limits |

| Particle Size | Granular or milled; matched to dosing equipment |

| Documentation | CoA per lot, TDS, SDS; feed declarations as needed |

Food/Pharma-Oriented DCP

| Appearance | White powder; controlled PSD |

|---|---|

| Calcium & Phosphorus | Guaranteed per grade |

| Insolubles | Low; for clarity and consistency |

| Heavy Metals | Meets food/pharma thresholds |

| Fluoride | Controlled as per relevant standard |

| Loss on Drying | Within specified range |

| PSD/Bulk Density | Targeted for tableting/flow |

| Documentation | CoA, TDS, SDS; dietary statements (Kosher/Halal) as needed |

Note: The above reflects common targets; verify exact specification limits with your supplier prior to qualification.

4) Applications & Functional Roles

DCP’s value proposition differs by sector. In feed, it provides bioavailable calcium and phosphorus for growth and bone health;

in food, it acts as a mineral fortifier and functional additive; in pharma, it contributes compressibility and calcium content to tablets and capsules.

| Industry | Function | How DCP Helps | Buyer Considerations |

|---|---|---|---|

| Feed Nutrition | Mineral supplementation | Supplies Ca & P for skeletal development and metabolic processes | Assay guarantees, impurities (e.g., fluoride), PSD for feed mills, flowability |

| Food & Beverage | Fortification & processing aid | Calcium enrichment; stabilizing/anti-caking roles in some systems | Food-grade documentation, contaminant thresholds, labeling |

| Pharmaceuticals/OTC | Direct compression excipient | Good compressibility; contributes calcium content | PSD control, heavy metals, moisture, consistent tableting behavior |

| Others (Industrial) | Fertilizer/intermediate | Source of P and Ca for certain formulations | Technical grade specs; cost-in-use focus |

Formulation Tips (Feed)

- Match PSD to mixer and dosing equipment to avoid segregation

- Control moisture to prevent caking and ensure dosing accuracy

- Audit fluoride and heavy metals per market regulation

Formulation Tips (Food/Pharma)

- Validate compressibility and dissolution for tablets

- Ensure label claims align with assay guarantees

- Use data-rich CoAs for faster QA release and audits

5) Production Routes & Process Controls

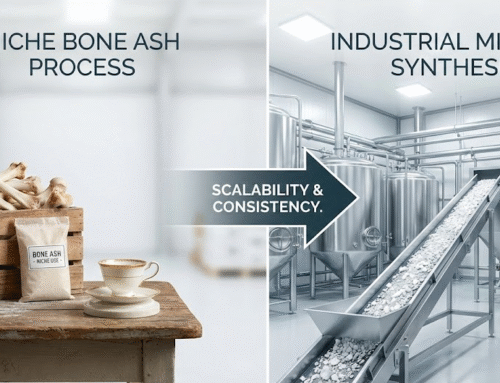

DCP can be manufactured via neutralization and precipitation steps using calcium and phosphate sources, followed by filtration, washing, drying, and milling/granulation.

The process window determines crystal hydration, particle structure, and impurity carryover. Robust controls are essential for predictable quality.

Raw Material Control

Verified purity of calcium and phosphate inputs minimizes downstream contaminants and improves nutrient guarantees.

Thermal & Hydration

Drying parameters and hydration state influence stability and flow; dihydrate vs anhydrous selection depends on application.

Milling & PSD

Controlled milling and classification produce consistent PSD, enabling reliable handling, tableting, and dispersion.

Process consistency + analytical discipline = fewer deviations, faster batch release, and lower total cost-in-use for the buyer.

6) Quality, Analytics & Documentation

Modern buyers expect data-rich certificates and fast documentation turnaround. A strong quality system accelerates qualification and reduces operational risk.

Core Analytics

- Assay guarantees for Ca and P

- Heavy metals profile; fluoride where applicable

- Moisture/LOD; bulk density

- PSD curves; sieve analysis

Documents

- CoA per lot; TDS; SDS

- Change-control policy and notification timelines

- Allergen/GMO/Kosher/Halal statements (as needed)

- Retained sample policy and traceability

System & Audits

- ISO-based QMS; GMP-aligned practices where relevant

- Supplier questionnaires completed promptly

- Audit readiness: batch records, SOPs, deviation handling

7) Regulatory & Compliance Considerations

Regulatory frameworks vary by jurisdiction and end-use (feed, food, pharma). Buyers should confirm permitted uses, contaminant limits, labeling, and documentation requirements for their target markets.

Proactive compliance shortens onboarding and prevents shipment delays.

| Domain | What to Verify | Buyer Action |

|---|---|---|

| Feed | Nutrient guarantees; fluoride & heavy metals; labeling | Obtain feed-grade declarations; align with local standards |

| Food | Food additive/fortification status; contaminants; allergen/GMO | Request regulatory letters; verify market-specific limits |

| Pharma/OTC | Excipient status; impurity thresholds; stability data | Align with pharmacopeial or internal specs; document control |

Reminder: Always align supplier documentation with your quality agreement and local regulations.

8) Supply Chain, Packaging & Storage

Packaging integrity and moisture control are decisive for DCP performance—especially in humid climates or long-haul logistics. Selecting the right pack type and palletization scheme reduces caking,

preserves PSD, and stabilizes dosing accuracy.

Packaging Options

- 25 kg multiply bags (lined) for standard operations

- FIBCs/Jumbo bags (e.g., 500–1000 kg) for bulk users

- Moisture-barrier liners and robust palletization

Storage

- Cool, dry warehouses; humidity control where feasible

- FEFO rotation to protect shelf life

- Avoid stacking that compromises bag integrity

Logistics & Resilience

- Forecast-based allocations; buffer stocks before seasonal peaks

- Diversified lanes or dual-route shipping for risk mitigation

- Clear lead-time models; expedite policies for spikes

Tip: For tropical/humid regions, specify enhanced liners and humidity indicators within pallets.

9) Sourcing Strategy: How to Choose a DCP Supplier

Selecting a DCP supplier is ultimately about risk control and cost-in-use. Beyond unit price, scrutinize quality systems,

documentation cadence, process transparency, and support responsiveness. The framework below aligns procurement and technical stakeholders.

- Capability & Reliability: Capacity, on-time metrics, multi-plant resilience, consistent lead times.

- Quality & Data: CoA depth (assay, impurities, PSD), rapid document turnaround, clear change-control discipline.

- Application Fit: Grade and PSD tuned to your process equipment, climate, and formulation goals.

- Contracting: Volume bands, service-level KPIs (delivery, CoA accuracy, claim response), product stewardship commitments.

- Support: Technical teams available for plant trials, troubleshooting, and optimization.

10) Market Outlook 2025: Demand, Risks & Opportunities

In 2025, DCP demand remains underpinned by feed nutrition programs and ongoing fortification in select food markets. Structured procurement—anchored by multi-quarter forecasts,

packaging adaptations, and qualification of dual routes—improves resilience against energy swings and logistics disruptions. The most competitive buyers emphasize specification harmonization

across plants and implement cost-in-use trials to capture efficiency gains.

Opportunities

- Upgrading PSD/flowability to reduce line stoppages and waste

- Digitized documentation for faster QA releases and audits

- Supplier-backed trials proving dosage optimization

Risks

- Route disruptions and freight volatility

- Humidity-induced caking affecting dosing accuracy

- Regulatory divergence across markets

Winners in 2025 treat DCP as a program, not a commodity—aligning specifications, packaging, logistics buffers, and supplier collaboration.

11) Sustainability & Future Directions

Sustainability criteria increasingly shape RFP scoring. Buyers request energy and water footprints, packaging recyclability, and waste minimization measures.

Manufacturers investing in cleaner utilities, effluent treatment, and smarter pack designs gain competitive advantage.

Water stewardship

Closed-loop practices

Waste minimization

Recyclable packaging

Digital CoA portals

Looking ahead, expect movement toward data-rich CoAs (including PSD curves), QR-coded batch records for traceability, and real-time shipment tracking

integrated with buyer ERP systems. These tools reduce friction, shorten lead times, and improve incident response.

12) FAQ for Buyers

Q1: How should I choose between powder and granular DCP?

Match PSD to your dosing and mixing equipment. Granular forms may reduce dust and improve flow in some feed mills, while fine powders may be preferred for certain food/pharma processes requiring tighter dispersion or tableting behavior.

Q2: What documents should I require for qualification?

Minimum set: CoA per lot, TDS, SDS, and change-control policy. Add feed/food/pharma statements as needed, plus allergen/GMO and dietary certificates for sensitive markets.

Q3: How can I reduce total cost-in-use?

Run supplier-supported plant trials to optimize PSD, packaging, and dosage. Improve warehouse humidity control and apply FEFO rotation. Use harmonized specs across plants to pool inventory and reduce slow-moving stock.

Q4: What pack sizes are common for DCP?

Standard 25 kg lined bags and bulk FIBCs (e.g., 500–1000 kg). Specify palletization and liners appropriate to your climate and handling equipment.

Q5: How do I manage humidity-driven caking?

Choose enhanced liners, keep pallets off the floor, avoid high stack pressures, and ensure ventilation. Where feasible, include humidity indicators and consider dehumidified storage for the wet season.

13) Why Partner with GJ Phosphate

GJ Phosphate supplies DCP with a focus on consistency, documentation depth, and application engineering.

Whether you require feed-grade nutrient guarantees or food/pharma-oriented specifications, we align product selection with your process window, quality targets, and compliance roadmap.

Application-Matched Grades

Powder or granular PSDs tailored to feed mills, food systems, or direct compression environments.

Documentation-Ready

Fast CoA/TDS/SDS delivery, retained samples, and formal change-control. Supplier questionnaires handled promptly.

Reliable Logistics

Flexible packaging, stable lead times, and forecast-based allocations to protect your production plan year-round.

Looking to evaluate DCP in a current formulation or plant trial? Our technical team can review parameters (PSD, bulk density, moisture, mixing time) and propose adjustments to stabilize performance at optimal dosage.