On paper, the quotation says “Monopotassium Phosphate, MKP, KH₂PO₄”. The product name is the same, the chemical formula is the same, and even the assay value looks similar across vendors.

Yet one supplier’s price is dramatically lower than another’s. Is someone overcharging, or is something else going on behind the scenes?

In reality, MKP is not a single product but a family of grades and processes: fertilizer grade, feed grade, food grade and pharma grade, produced from different phosphoric acid routes (thermal, wet-process and purified wet-process).

If buyers do not match grade, process and application, the cheapest choice on the spreadsheet can become the most expensive mistake in production.

1) Same Name, Different Reality: Why MKP Prices Vary So Much

Monopotassium phosphate (MKP, KH₂PO₄) is widely used in fertilizers, feed premixes, food and beverage formulations, and even pharmaceutical or fermentation applications.

In chemical terms, it is a single compound. In the marketplace, however, “MKP” can mean very different things depending on:

- The upstream phosphoric acid route (thermal, wet-process, purified wet-process).

- The final product grade (fertilizer, feed, food, pharma).

- The impurity profile (metals, fluoride, sulfate, insolubles, organics).

- The production technology and process control level.

This is why the same product name “MKP” can be offered at very different prices—even if both COAs formally mention “KH₂PO₄ ≥ 98%”.

The key for purchasing managers is to stop thinking of MKP as “one product with many prices” and start seeing it as “multiple grades and routes with different cost structures and risk levels”.

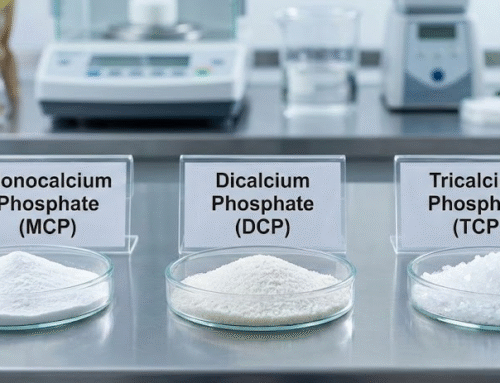

2) Four MKP Grades: Fertilizer, Feed, Food and Pharma

In practice, MKP is normally categorized into four broad grades, each designed for a very different market:

| MKP Grade | Typical Applications | Impurity Level | Regulatory Expectations |

|---|---|---|---|

| Fertilizer grade MKP | Water-soluble fertilizers, foliar sprays, hydroponics | Highest impurities among the four grades | Agricultural or technical standards; not food/feed |

| Feed grade MKP | Mineral premixes, animal nutrition | Lower impurities than fertilizer grade | Feed regulations (e.g. fluorine, heavy metals) |

| Food grade MKP | Food and beverages, buffering, leavening, stabilizing | Low impurities, meets food additive standards | Food-grade standards (FCC, GB, EU, etc.) |

| Pharma grade MKP | Pharmaceuticals, injectables, dialysis solutions, fermentation media | Ultra-low impurities, very tight controls | Pharmacopoeia specifications (USP, EP, etc.) |

All four share the same chemical formula, but they are not interchangeable.

Trying to apply a lower grade in a higher-grade application may not only lead to technical issues, but also to serious safety and compliance risks.

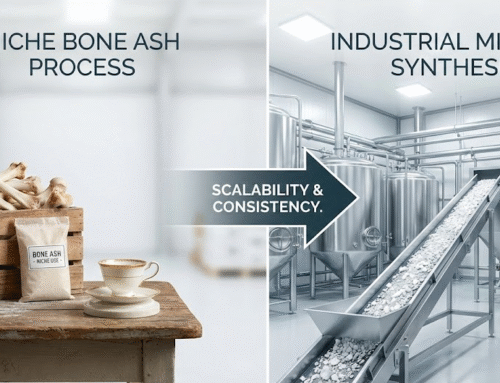

3) The Hidden Driver: Phosphoric Acid Route (Thermal vs Wet-Process)

The next layer behind MKP pricing is the source of the phosphoric acid used to manufacture it.

MKP is produced by neutralizing phosphoric acid with a potassium source (often KOH or K₂CO₃), then crystallization and drying.

But there are three main ways to obtain that phosphoric acid:

- Thermal-process phosphoric acid (high cost, very high purity).

- Wet-process phosphoric acid (low cost, high impurity).

- Purified wet-process phosphoric acid (intermediate cost and quality).

For buyers, understanding these routes is essential to explain why one food-grade MKP price can be significantly higher than another—even if both claim similar assay values.

3.1 Thermal-Process Phosphoric Acid

Thermal phosphoric acid is produced through a high-temperature, high-energy route:

- Phosphate rock is smelted in an electric furnace to produce elemental yellow phosphorus.

- Yellow phosphorus is burned in air to form phosphorus pentoxide (P₂O₅) gas.

- The gas is then absorbed in water to form phosphoric acid (H₃PO₄).

This route has a very high energy cost, because electric furnaces typically consume:

- Over 12,000–14,000 kWh of electricity per tonne of yellow phosphorus.

The advantages of thermal-process acid are:

- Very low impurity levels, especially heavy metals and insoluble matter.

- Excellent clarity and color, even for concentrated acids.

- Very consistent quality from batch to batch.

- Suitable as the basis for high-purity food, pharma and electronic-grade phosphates.

In short, thermal-route MKP is based on an inherently cleaner upstream process and is therefore more expensive, but also more reliable for high-end applications.

3.2 Wet-Process Phosphoric Acid

Wet-process phosphoric acid is produced via a lower-cost, large-scale chemical route:

- Phosphate rock is digested with sulfuric acid.

- The reaction produces phosphoric acid and calcium sulfate (gypsum) as a by-product.

- The slurry is filtered to separate the phosphoric acid solution and gypsum solids.

Its main characteristics are:

- Low energy consumption compared to thermal process.

- Lower capital expenditure and large fertilizer complexes.

- High throughput and low cost per tonne.

But it also carries impurities from the rock into the acid:

- Higher levels of iron and other metal ions.

- Fluoride, sulfate and organic impurities.

- Higher insoluble content and turbidity.

- Color that ranges from yellowish to dark, depending on rock and process.

This route is ideal for fertilizer production but usually not suitable for direct food or pharma applications without further purification.

3.3 Purified Wet-Process Phosphoric Acid

To enter higher-value markets, some producers further treat wet-process acid through:

- Solvent extraction.

- Ion exchange or adsorption.

- Advanced filtration and clarification steps.

- Defluorination and decolorization.

This generates purified wet-process phosphoric acid, which:

- Has significantly lower metal and insoluble content than crude wet acid.

- Offers better color and clarity.

- Is cheaper than thermal acid but more expensive than crude wet-process acid.

However, it still has limitations:

- Fluoride and sulfate can remain at higher levels than in thermal acid.

- Trace organics may still be present and affect color or taste.

- Quality is more sensitive to rock quality and process stability.

Many of the “surprisingly cheap” food-grade MKP offers in the market are in fact made from purified wet-process acid, not from thermal-process acid.

This does not automatically make them bad, but it does change their risk profile and suitability for certain applications.

4) Technical Differences Between MKP Grades (What Buyers Should Check)

Beyond marketing labels like “fertilizer grade” or “food grade”, purchasers should understand which parameters actually differentiate the grades technically.

The most important factors are:

- Purity (assay).

- Heavy metals (Pb, As, Cd, Hg, etc.).

- Fluoride and sulfate.

- Water-insoluble matter and clarity.

- Microbiological limits (for food and pharma).

- Batch-to-batch consistency.

4.1 Fertilizer-Grade MKP

Fertilizer-grade MKP is primarily used as a source of water-soluble P and K for plants (e.g. 0-52-34).

Key features include:

- Focus on nutrient content (P₂O₅ and K₂O) rather than impurity control.

- Higher tolerance for heavy metals and fluoride compared to food or feed.

- Water solubility is important, but slight haze or color is acceptable in many uses.

- Phosphoric acid origin is typically wet-process.

For agricultural use, it is unnecessary and uneconomical to use thermal-route MKP.

However, using fertilizer-grade MKP in a food application is completely inappropriate.

4.2 Feed-Grade MKP

Feed-grade MKP is used in animal nutrition as a source of phosphorus and potassium.

Requirements sit between fertilizer and food grade:

- Impurities like fluoride must be controlled for animal safety.

- Heavy metals have stricter limits than fertilizer, but often looser than food standards.

- The phosphoric acid may be purified wet-process, or a blend, depending on local regulations.

If feed-grade MKP is mistakenly used in human food, heavy metals or other impurities may exceed food-grade limits, creating regulatory and safety issues.

4.3 Food-Grade MKP

Food-grade monopotassium phosphate is used as:

- A buffering agent and pH regulator.

- A nutrient source in beverages and nutrition products.

- A component in baking powders and leavening systems.

- A stabilizer or mineral source in dairy and plant-based beverages.

Typical characteristics:

- Meets FCC, GB or EU food additive standards.

- Low and controlled heavy metals (Pb, As, etc.).

- Low fluoride and sulfate suitable for human consumption.

- Low water-insoluble matter and good solution clarity.

- Often based on thermal-process phosphoric acid for sensitive applications.

Some food-grade MKP in the market is made from purified wet-process acid.

It may meet the written limits of a food standard, but can still show differences in long-term clarity, stability, color or taste—especially in clear beverages or demanding applications.

4.4 Pharma-Grade MKP

Pharma-grade MKP goes even further:

- Must comply with pharmacopoeia monographs (e.g. USP, EP).

- Ultra-low heavy metals and specified elemental impurities.

- Microbiological controls, where relevant.

- Very tight specifications and validated manufacturing processes.

- Almost always produced from high-purity thermal acid routes.

It is technically possible—but rarely economical—to use pharma-grade MKP in food or feed. The cost is generally too high for large-volume use.

4.5 Summary Table: MKP Grades vs Key Parameters

| Parameter | Fertilizer Grade MKP | Feed Grade MKP | Food Grade MKP | Pharma Grade MKP |

|---|---|---|---|---|

| Phosphoric acid route | Wet-process | Purified wet / wet | Thermal or purified wet | Thermal |

| Heavy metals control | Basic, fertilizer-focused | Moderate (feed limits) | Strict (food limits) | Very strict (pharma) |

| Fluoride limits | High tolerance | Controlled | Low tolerance | Very low tolerance |

| Insoluble matter / clarity | Not critical | Moderately important | Important, especially for beverages | Highly critical |

| Typical price level | Lowest | Low to medium | Medium to high | Highest |

| Typical applications | Fertilizer, agriculture | Feed premix, animal nutrition | Food, beverages, bakery, dairy | Pharmaceutical and special medical uses |

4.6 Difference Between MKP Produced from H₃PO₄ + KCl vs H₃PO₄ + KOH

Although both routes generate monopotassium phosphate (KH₂PO₄), the choice of potassium source creates two very different quality and impurity profiles.

A) MKP Produced from Phosphoric Acid + Potassium Chloride (H₃PO₄ + KCl)

This route is mainly used for low-cost fertilizer-grade MKP.

Characteristics:

- Lower production cost due to inexpensive potassium chloride (KCl).

- Introduces chloride ions (Cl⁻) into the system, which cannot be completely removed.

- Typically higher impurity load (Na, Cl and other trace ions).

- More variation in color and clarity.

- Greater risk of residual salts affecting solubility and stability.

Limitations:

- Not suitable for food, beverage, feed or pharma applications.

- Chloride ions may:

- Affect taste and mouthfeel in food and beverage systems.

- Increase corrosion risk in certain industrial applications.

- Interfere with formulations that are sensitive to halides.

This route is economical but should be restricted to agricultural and some technical industrial uses where chloride and higher impurity levels are acceptable.

B) MKP Produced from Phosphoric Acid + Potassium Hydroxide / Potassium Carbonate (H₃PO₄ + KOH or K₂CO₃)

This is the standard route for feed-grade, food-grade and pharma-grade MKP.

Characteristics:

- Uses high-purity potassium hydroxide (KOH) or potassium carbonate (K₂CO₃) as the potassium source.

- No chloride ions are introduced into the process.

- Lower impurity levels and better control of heavy metals and insolubles.

- Consistently better color and solution clarity after dissolution.

- More stable performance in beverage, nutrition and pharmaceutical systems.

Advantages:

- Can meet FCC, GB, EU and pharmacopoeia specifications for food and pharma use.

- Preferred for:

- Clear and sparkling beverages.

- High-end nutrition drinks and functional beverages.

- Bakery systems and premixes with strict visual requirements.

- Fermentation and pharmaceutical-related applications.

Although this route has a higher raw material cost than KCl-based production, it delivers the purity, stability and safety margin required for sensitive applications.

For any human food, beverage, feed or pharma use, MKP produced from H₃PO₄ + KOH / K₂CO₃ should be the default choice.

5) Application-Specific Risks: What Happens If You Use the Wrong MKP?

To understand why grade selection matters, it helps to look at typical “failure modes” when lower-grade MKP is used in higher-grade applications.

5.1 Using Fertilizer-Grade MKP in Food or Beverage

Potential consequences include:

- Heavy metals or fluoride exceed food-grade limits.

- Off-color or turbidity development in beverages.

- Undesirable taste or mouthfeel changes over time.

- Regulatory non-compliance and recall risk.

Even if the product appears “clear enough” initially, long-term stability and safety are not guaranteed.

5.2 Using Feed-Grade MKP in Human Food

Feed-grade MKP controls certain impurities, but its limits and testing focus are different from food-grade:

- Some parameters may be outside food specifications even if they are acceptable for animals.

- Documentation, traceability and certifications may be insufficient for food audits.

- Brand risk is significant if a feed-grade material is discovered in a food product.

5.3 Using Purified Wet-Process Food-Grade MKP in Sensitive Applications

In many food applications, purified wet-process MKP can work well.

However, in very sensitive systems such as:

- Clear or sparkling beverages.

- High-end nutrition drinks.

- Delicate flavors or colors.

Trace impurities can still lead to:

- Haze or sediment formation over shelf life.

- Color drift or yellowing.

- Subtle but noticeable flavor changes.

In these segments, thermal-route MKP may provide a more robust solution despite the higher price.

5.4 Under-Specifying MKP for Pharma and Fermentation

In pharmaceutical or fermentation uses, impurities can:

- Interfere with active ingredient stability.

- Inhibit microbial growth in fermentation media.

- Complicate regulatory approval or batch validation.

For these cases, pharma-grade or high-purity thermal-route MKP is typically required.

6) Why Buyers Must Always Tell Suppliers the Application

A critical principle in MKP purchasing is simple but often overlooked:

When you inquire about MKP, you must clearly tell the supplier what the product will be used for.

If you only ask: “Please quote MKP, KH₂PO₄, 25 kg bags, CIF”, the supplier has no context.

Some will quote fertilizer-grade, some feed-grade, some food-grade; a few might propose pharma-grade.

The cheapest quote may not be wrong—just completely unsuitable for your purpose.

By explicitly stating your application, for example:

- “MKP for water-soluble fertilizer.”

- “MKP for animal feed premix.”

- “Food-grade MKP for clear beverages.”

- “High-purity MKP for a pharma-related application.”

You give the supplier the chance to:

- Select the right grade and phosphoric acid route.

- Clarify whether your expectations match the offered material.

- Warn you if a cheaper grade may not meet your performance or compliance needs.

For a responsible professional supplier, this information is essential to make a technically sound recommendation.

7) How to Select the Right MKP for Your Application

Below is a practical guide that purchasing and technical teams can use together when selecting monopotassium phosphate.

7.1 Step 1 – Define the End-Use Category

Start by categorizing your application:

- Fertilizer or agricultural use?

- Animal feed or premix?

- Human food and beverage?

- Pharma, medical or fermentation use?

7.2 Step 2 – Match MKP Grade to Category

A simple rule of thumb:

- Fertilizer applications → fertilizer-grade MKP.

- Animal nutrition → feed-grade MKP.

- Standard food applications → food-grade MKP.

- Highly sensitive food/beverage or pharma → thermal-route food or pharma-grade MKP.

7.3 Step 3 – Decide on Phosphoric Acid Route

Within food-grade:

- For clear beverages and very sensitive products, thermal-route MKP is usually safer.

- For less sensitive food applications (e.g. bakery mixes, some dairy), purified wet-process MKP may be sufficient, given proper testing.

7.4 Step 4 – Check Key Specifications in the COA

Regardless of grade, buyers should look at:

- Assay (KH₂PO₄ or P₂O₅ / K₂O content).

- Heavy metals (Pb, As, Cd, Hg) and their limits.

- Fluoride and sulfate levels.

- Water-insoluble matter and clarity.

- pH of solution and any relevant functional parameters.

- Microbiological counts for food and pharma applications.

If any of these are missing or close to regulatory maxima, further questions should be asked.

7.5 Step 5 – Ask About Phosphoric Acid Origin

Explicitly confirm with the supplier:

- “Is this MKP produced from thermal phosphoric acid or wet-process (or purified wet-process) phosphoric acid?”

- “Can you specify the acid route on the specification or contract if necessary?”

7.6 Step 6 – Run Trials in Your Own Formulations

For food, beverage and pharma, lab and pilot trials are essential:

- Check clarity and color over shelf life.

- Monitor pH and taste stability.

- Observe any precipitation or haze formation.

- Compare performance between thermal and purified wet-process options if cost is a concern.

7.7 Step 7 – Consider Total Cost, Not Just Price per Tonne

Cheaper MKP may have hidden costs:

- Increased risk of quality issues or customer complaints.

- More strict incoming QC and testing required.

- Higher probability of production disruptions.

- Potential regulatory or brand damage if specifications are not truly met.

The “cheapest on paper” option is not always the lowest total cost in a real supply chain.

8) The Role of a Professional Supplier in MKP Sourcing

A specialized phosphate supplier acts as a bridge between multiple MKP producers and end users with very different requirements.

From the Producer Side

- Understands which factories produce fertilizer-, feed-, food- or pharma-grade MKP.

- Knows which plants use thermal, wet-process or purified wet-process phosphoric acid.

- Evaluates producers based on impurity control, consistency and documentation quality.

- Monitors capacity, lead times and export experience.

From the Buyer Side

- Helps define the appropriate grade and route for each application.

- Explains price differences between offers with the same product name.

- Arranges samples and multi-batch COAs for evaluation.

- Supports regulatory and technical documentation needs for audits.

Factories can only sell what they produce; a professional supplier can compare multiple qualified sources and recommend the most suitable option for a specific buyer and application scenario.

9) Recommended MKP Purchasing Workflow for Professional Buyers

To build a robust MKP sourcing strategy, purchasing teams can follow this structured approach:

- Map your internal demand:

Identify all applications where MKP is used (fertilizer blends, feeds, beverages, bakery, etc.). - Assign required grade per application:

Decide, jointly with QA and R&D, which applications need fertilizer-, feed-, food- or pharma-grade MKP. - Decide on acceptable phosphoric acid routes:

For sensitive food and pharma, define whether only thermal-route MKP is acceptable, or whether purified wet-process may be considered with additional testing. - Prepare clear RFQs:

When requesting quotations, always state the grade, application and any critical regulatory standards to be met (FCC, GB, EU, USP, etc.). - Shortlist suppliers with expert support:

Work with a specialized phosphate supplier to identify reliable MKP producers and exclude those whose route or controls are not suitable. - Request and review multi-batch COAs:

Look for batch-to-batch stability in impurities, not just the headline assay. - Conduct in-house evaluation:

Perform lab and pilot trials for critical applications to confirm performance and stability. - Finalize grade and supplier per application:

Document which MKP source is approved for which end product, and under what conditions. - Periodically review and update:

As market prices, regulations and internal requirements evolve, revisit the sourcing strategy annually.

10) Conclusion: Price, Grade and Route Must Be Aligned

When you see two MKP offers with the same name but very different prices, the explanation is almost always hidden in:

- The grade (fertilizer, feed, food, pharma).

- The phosphoric acid route (thermal, wet-process, purified wet-process).

- The impurity profile and consistency behind the COA.

The right question is not “Why is this MKP more expensive?”, but rather:

- “Is this MKP the right grade and route for my application?”

- “What risks am I accepting if I buy the cheapest option?”

- “Have I clearly told my supplier what I will use this MKP for?”

For fertilizer use, lower-cost wet-process MKP is often perfectly appropriate.

For animal feed, dedicated feed-grade MKP is needed.

For human food and beverages, food-grade—and in some cases thermal-route—MKP is the safer choice.

For pharma, only the highest purity levels will do.

By combining a clear understanding of grades and routes with support from a knowledgeable professional supplier, buyers can:

- Explain price differences internally with confidence.

- Protect their brands and end products from avoidable risks.

- Optimize total cost over the full product life cycle, not just at the purchase order level.

If you are comparing MKP offers now, or planning to redesign your phosphate sourcing strategy, a structured discussion on grade, route and application is the best starting point.

Discuss MKP Sourcing with Our Team

Learn More About GJ Phosphate

Disclaimer: The information in this article is intended for technical and commercial guidance only.

Users are responsible for verifying suitability, regulatory compliance and performance in their own processes before finalizing any specification or purchase decision.