Many purchasing managers are puzzled: the product name on two phosphate offers is identical, the specification looks similar, yet one price is 30–100% higher than the other.

Many purchasing managers are puzzled: the product name on two phosphate offers is identical, the specification looks similar, yet one price is 30–100% higher than the other.

Is someone overcharging, or is the cheaper material “too good to be true”?

The real reason lies upstream, in how the phosphoric acid is produced:

thermal process VS wet-process VS purified wet-process.

1) Why Identical Product Names Can Have Big Price Gaps

In day-to-day purchasing, it is common to see offers like “STPP 94% food grade” or “DKP food grade” from different suppliers with prices that differ by hundreds of dollars per ton.

On paper, the product name, purity and even packaging may look similar.

The core reason is simple but often not clearly explained:

Most phosphate salt cost and quality differences come from the origin of the phosphoric acid used:

thermal phosphoric acid, wet-process phosphoric acid, or purified wet-process phosphoric acid.

Once you understand these three routes, you can read between the lines of any quotation and understand why “the same” phosphates are not really the same.

2) Three Upstream Routes: Thermal, Wet-Process and Purified Wet-Process

Almost all phosphates (DKP, MKP, DAP/MAP, STPP, SHMP, MCP, DCP, TCP, etc.) are made by neutralizing

phosphoric acid. But there are three very different ways to obtain that phosphoric acid:

| Route | Typical Cost Level | Purity Level | Insolubles & Metals | Typical Applications |

|---|---|---|---|---|

| Thermal phosphoric acid | Highest | ★★★★★ (very high) | Very low | Food, pharma, electronics, high-end chemicals |

| Wet-process phosphoric acid | Lowest | ★★☆☆☆ (low) | High | Fertilizer, low-end industrial uses |

| Purified wet-process phosphoric acid | Medium | ★★★☆☆ (medium) | Medium to low | Some food, feed, mid-level industrial applications |

If you do not know which route your phosphate salt comes from, you cannot correctly assess either its cost structure or its risk profile.

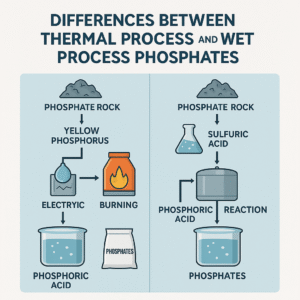

3) Thermal Phosphoric Acid: High-Energy, High-Purity Route

Thermal phosphoric acid is produced through an energy-intensive, metallurgy-style process:

- Phosphate rock is smelted in an electric furnace to make elemental yellow phosphorus.

- Yellow phosphorus is burned to form phosphorus pentoxide (P2O5).

- The P2O5 gas is absorbed in water to generate phosphoric acid.

The critical cost driver is the electric furnace:

- Producing one ton of yellow phosphorus can consume more than 12,000–14,000 kWh of electricity.

- This makes thermal phosphoric acid intrinsically expensive and sensitive to power prices.

- Only plants with large, modern furnaces and stable power supply can operate competitively.

At the same time, this route offers unique advantages:

- Very high reaction temperature and well-controlled chemistry remove many impurities from the start.

- Heavy metals and insolubles are extremely low.

- The acid is naturally clear, with very low color without heavy post-treatment.

- It can be upgraded to food-grade, pharma-grade or electronic-grade phosphates.

In simple terms: thermal acid is expensive because it is clean from birth.

It is not “filtered into purity”; the upstream process inherently produces a very clean acid.

4) Wet-Process Phosphoric Acid: Low-Cost, High-Impurity Route

Wet-process phosphoric acid follows a very different logic:

- Phosphate rock is digested with sulfuric acid.

- The reaction generates phosphoric acid and calcium sulfate (phosphogypsum) as a by-product.

- The slurry is filtered to separate the acid from the gypsum solids.

Its main advantages are:

- No electric furnace, no yellow phosphorus production.

- Lower capital investment and energy consumption.

- Large-scale fertilizer complexes can achieve strong economies of scale.

But the trade-offs are significant:

- Many impurities in the rock (metals, fluorides, organics) dissolve into the acid.

- Insoluble particles and suspended solids remain.

- The acid is often dark, grey or brownish without additional treatment.

- Heavy metals and fluoride contents are high relative to food-grade requirements.

Standard wet-process phosphoric acid is therefore mainly used for:

- Fertilizers (MAP, DAP, compound NPK)

- Low-end industrial cleaners or scale control agents

- Applications where color and trace impurities are less critical

5) Purified Wet-Process: In-Between Cost, Hidden Risks

To supply higher value markets, some producers further treat wet-process acid using:

- Solvent extraction

- Filtration and clarification

- Ion exchange or adsorbents

- Defluorination and decolorization steps

This gives rise to purified wet-process phosphoric acid, which:

- Has significantly lower metals and insolubles than crude wet acid.

- Can achieve reasonable color and clarity.

- It is much cheaper than thermal acid, though more costly than crude wet acid.

However, even with good purification:

- Fluoride, sulfate, and some organic residues are very difficult to remove completely.

- Trace impurities can still cause haze, sediment, yellowing, taste issues or pH drift in sensitive food and beverage systems.

- Quality can be highly dependent on rock source and process stability.

The purified wet-process is the main reason why the market becomes confusing:

The product can look similar to thermal-grade on paper, yet its long-term performance and safety margin are not the same.

6) How These Routes Translate into Phosphate Salt Price and Quality

Once the phosphoric acid is produced, it is neutralized with various alkalis (NaOH, KOH, NH3, CaCO3, etc.) to make phosphate salts such as MKP, DKP, STPP, SHMP, MCP, DCP, and more.

The acid route determines both the cost and the risk profile of the final phosphate.

6.1 Cost Structure in Simple Terms

A simplified view:

- Thermal-route phosphates carry the cost of yellow phosphorus and furnace electricity → the highest price.

- Wet-route phosphates inherit low-cost sulfuric acid chemistry → lowest price.

- Purified wet-route phosphates sit in between, adding purification cost on top of the wet-process baseline.

For example (illustrative only):

- Food-grade MKP (monopotassium phosphate) from thermal acid might be priced at X.

- Purified wet-process MKP might be 30–50% lower.

- Crude wet-process MKP (industrial/fertilizer grade) may be only 50–60% of the thermal price—but is not suitable for sensitive foods.

6.2 Quality and Performance Differences

Compared side by side:

| Aspect | Thermal-Route Phosphates | Purified Wet-Route Phosphates | Crude Wet-Route Phosphates |

|---|---|---|---|

| Color & clarity | Very white, clear, uniform granules | White to off-white, may have a slight tint | Greyish/yellowish, often dull appearance |

| Insoluble matter | Very low | Moderate, often within basic food specs | Higher, visible particles or residue |

| Heavy metals (Pb, As, etc.) | Very low, easy to meet strict limits | Reduced vs wet, but more variable | Higher, mainly for fertilizer/industrial |

| Fluoride/sulfate residues | Very low | Often, the “last mile” impurity & difficult to remove | High |

| Batch-to-batch stability | High | Depends heavily on process control | Variable |

| Suitable markets | High-end food, pharma, beverage, electronics | Mid-level food, feed, and some industrial | Fertilizer and low-end industrial only |

This is why two “food-grade” phosphates with the same name can still behave very differently in a clear beverage, in a sensitive meat application, or in a bakery premix.

The acid route defines the underlying risk.

7) Where Thermal-Route Phosphates Are Non-Negotiable

Certain applications are so sensitive to impurities, color, or safety margins that thermal-route phosphates are strongly preferred or effectively mandatory:

- Clear and transparent beverages: even small impurities cause haze, sediment, or color change.

- Infant nutrition and specialized medical foods: ultra-low heavy metals and predictable purity are essential.

- Dairy and plant-based beverages: insolubles, fluoride, and metals affect stability, flavor, and shelf life.

- High-end bakery and premixes: black specks or off-color from impurities are unacceptable.

- Seafood and meat injection systems: off-color or off-flavor from impurities can ruin high-value products.

- Electronics and surface treatment: any contamination may cause defects.

In these segments, choosing a cheaper, non-thermal route may save money on paper but create far greater losses through rejected batches, product recalls, or brand damage.

8) Where Wet / Purified Wet Phosphates Are Acceptable

On the other hand, many applications do not need the ultra-purity of thermal-route phosphates.

In such cases, wet or purified wet-process materials can offer an attractive cost–performance balance:

- Fertilizers and agricultural formulations.

- Detergents and industrial cleaners.

- Some water treatment, ceramics, leather, dye, and metal-processing applications.

- Certain lower-sensitivity food uses where specifications are clear and well controlled.

The key is to match:

- Impurity tolerance of your application, and

- The true impurity profile of the phosphate you are buying.

A professional supplier could help you decide when purified wet-process is sufficient and when you should invest in thermal-grade.

9) How Buyers Can Detect Mislabeling and Avoid Pitfalls

Because purified wet-process phosphates can look similar to thermal-grade, some low-cost suppliers may blur the distinction.

Buyers need a simple, practical checklist to protect themselves.

9.1 Do Not Rely on Appearance Alone

White color and uniform granules do not automatically mean “thermal”.

Appearance can be improved with process tweaks, but hidden impurities may remain.

9.2 Read the COA Carefully

Look beyond assay and moisture. Key indicators include:

- Iron (Fe)

- Lead (Pb), arsenic (As), cadmium (Cd), mercury (Hg)

- Fluoride (F⁻)

- Sulfate (SO₄²⁻)

- Water-insoluble matter

If values are close to regulatory maximums or vary widely between batches, the product is unlikely to be thermal-route.

9.3 Simple Solution Clarity Tests

Dissolve the phosphate in deionized water at typical use concentration:

- Thermal-route phosphates usually give a clear, colorless solution.

- Wet or purified wet materials may show slight yellow/grey tint, haze or sediment over time.

9.4 Ask Direct Questions About Acid Origin

Straightforward questions can be very revealing:

- “Is this phosphate manufactured from thermal phosphoric acid or wet-process phosphoric acid?”

- “Do you have your own thermal phosphoric acid plant, or do you buy from others?”

- “Can you provide documentation on the phosphoric acid origin?”

Vague answers like “it is good food grade, very white” without specifying the route are a warning sign.

9.5 Compare Multiple Batches

Request COAs for several recent batches.

Large fluctuations in metal content, insolubles, or color indicate unstable process control—more common in lower-cost wet-route sources.

10) The Real Value of a Professional Supplier in Phosphate Sourcing

In a market where the same product name can hide very different origins and risks, a specialized

phosphate supplier adds value far beyond “middleman pricing”.

What a Professional Supplier Does

- Qualifies multiple thermal, wet, and purified wet-process producers.

- Understands each factory’s acid route, cost structure, and typical impurity profile.

- Matches the right phosphate origin to the buyer’s industry and risk tolerance.

- Filters out suppliers that mislabel wet-process products as thermal-grade.

Benefits for Buyers

- Transparent explanation of why prices differ for the “same” product name.

- Lower risk of hidden quality problems and recalls.

- Access to multiple factories without managing each relationship individually.

- Support with documentation, third-party testing and export logistics.

Factories can only sell their own products; buyers can compare them side by side and design a sourcing portfolio that balances cost, quality, and risk for themselves.

11) A Practical Procurement Workflow for Phosphate Buyers

To turn these concepts into daily practice, purchasing teams can follow a simple workflow:

- Classify your applications:

Which products are high-risk (clear beverages, infant nutrition, premium meat/seafood, etc.) and which are lower-risk (fertilizer, industrial cleaning)? - Define acceptable acid routes:

For each application, decide whether you require thermal, can accept purified wet, or can use crude wet-process. - Align specifications with route:

Set realistic but safe limits for metals, insolubles, fluoride and sulfate, based on route and regulation. - Work with a specialist partner:

Shortlist qualified factories, request multi-batch COAs and, if needed, independent lab tests. - Run internal trials:

Evaluate not only lab specs but also real product behavior: clarity, stability, taste, color, shelf life. - Establish a dual-sourcing strategy:

For critical products, secure at least two qualified sources (possibly from different routes) to balance security and cost. - Review annually:

Revisit sourcing decisions as markets, energy prices and technology evolve.

12) Conclusion: Cheap vs Correct Is Not the Same Question

When you understand the difference between thermal, wet-process, and purified wet-process phosphoric acid, you also understand why two phosphates with the same name can have very different prices.

The choice is not simply “expensive vs cheap”, but rather:

- Which acid route does this product come from?

- Is that route appropriate for my application and risk profile?

- Does the price reflect a real cost structure or a hidden compromise?

For food, beverage, nutrition, and high-end industrial applications, buying only on price is a dangerous shortcut.

Working with a knowledgeable partner can help you:

- See behind the product name and understand the real origin.

- Choose the right route (thermal vs wet vs purified wet) for each product line.

- Balance total cost, performance, and safety in a structured way.

If you are reviewing your phosphate sourcing strategy or comparing offers that look similar but are priced very differently, our team is ready to help you analyze the options and build a more robust purchasing framework.

Discuss Your Phosphate Purchasing Plan

Learn More About GJ Phosphate

Disclaimer: The information in this article is provided for technical and commercial guidance only.

Always verify performance and compliance in your own products and consult your internal quality and regulatory teams before changing grade, route or supplier.