In 2025, procurement leaders and technical teams across oral care, feed nutrition, food processing, and industrial formulations

are recalibrating for quality, compliance, and resilient supply chains. This report distills the essentials on

Sodium Monofluorophosphate (SMFP) and Dicalcium Phosphate (DCP), and offers a practical playbook

for choosing a reliable phosphate supplier. Authored by GJ Phosphate.

Executive Summary

Key Takeaways for Procurement & Technical Teams

- SMFP remains a cornerstone active in oral care for anti-caries benefits; buyers should prioritize assay, impurity control, and stability data.

- DCP is a dependable source of calcium and phosphorus across feed and pharma; particle-size, flowability, and bioavailability drive cost-in-use.

- Supplier reliability depends on documentation depth (CoA/TDS/SDS), change-control discipline, and logistics responsiveness. Learn more about GJ Phosphate and our quality system.

- Compliance frameworks (food, feed, pharma, industrial) require auditability and clear labeling; harmonized specs ease multi-site adoption.

- Sustainability and risk management now influence RFP scores—ask for energy, water, and packaging footprints where relevant.

Rather than chasing spot prices alone, leading buyers are committing to programmatic partnerships with phosphate manufacturers

who can deliver predictable quality, regulatory support, and shipment reliability across seasons and regions.

Market Context: 2025 Phosphate Demand

Global phosphate consumption remains underpinned by diversified end-use segments. In oral care, SMFP sits at the center of

fluoride-based anti-caries formulations; in nutrition, DCP supports mineral supplementation across feed and select pharma products.

Meanwhile, cross-cutting demand from food processing and industrial formulations stabilizes baseline volumes and encourages continuous process improvements.

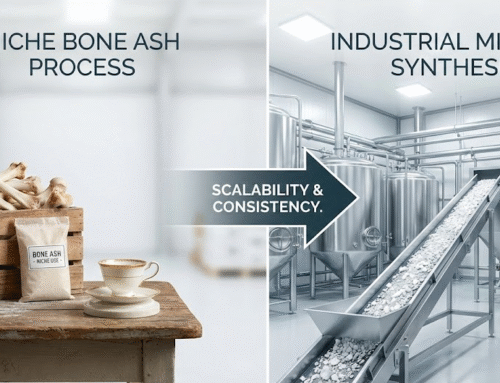

Stability Over Cycles

Unlike niche additives, SMFP and DCP enjoy structural demand anchored to everyday consumer and agricultural products.

This supports steady capacity utilization and provides buyers with opportunities to secure allocation under forecasted programs.

Quality as a Differentiator

Buyers are ranking suppliers not just on price but on documentation quality, analytical transparency,

and change-control rigor. This favors manufacturers invested in GMP-aligned systems and data-rich CoAs.

Sodium Monofluorophosphate (SMFP): Properties & Uses

SMFP (Sodium Monofluorophosphate) is widely used in oral care products due to its fluoride contribution and compatibility with typical toothpaste bases.

For B2B buyers, the decisive factors are assay consistency, impurity control (particularly heavy metals and fluoride release profiles), and documented stability under storage and transport conditions.

Typical Specification Snapshot

| Assay (as SMFP) | ≥ 98% (on dry basis) – example target range |

|---|---|

| Fluoride Content | Conforms to product standard; controlled release characteristics |

| Insolubles | Low insoluble content for smooth dispersion |

| Particle Size | Fine powder; customized PSD for paste homogeneity |

| Loss on Drying | Within agreed thresholds for stability |

| Documentation | CoA per lot, TDS, SDS, change-control policy |

Application Considerations

- Compatibility: Works with common toothpaste bases; check interactions with abrasives and humectants.

- Stability: Packaging with moisture control; rotation policy for FEFO (First Expire, First Out).

- Process: Controlled addition and dispersion to avoid agglomeration and ensure uniform fluoride distribution.

- Regulatory: Support for target markets; labeling alignment with local requirements.

Note: Exact specification targets should be validated against your technical standard and market regulations.

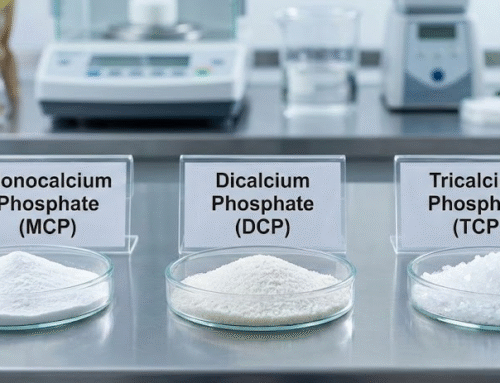

Dicalcium Phosphate (DCP): Applications & Quality

DCP (commonly Dicalcium Phosphate Dihydrate for feed; anhydrous or dihydrate for select pharma/food uses) serves as a mineral source

of calcium and phosphorus. In feed, consistency in nutrient content and flow properties drives formulation accuracy and plant efficiency.

Typical Specification Snapshot

| Assay (as DCP) | Meets agreed nutrient levels (Ca & P) |

|---|---|

| Moisture | Controlled for storage stability and flow |

| Particle Size | Granular/powder options to fit dosing equipment |

| Heavy Metals | Within feed/pharma limits as applicable |

| Bulk Density | Specified for transport and silo handling |

| Documentation | CoA per lot, TDS, SDS; feed/pharma statements where needed |

Application Considerations

- Flowability & Caking: Match PSD and moisture to climate and equipment; consider anti-caking where permitted.

- Bioavailability: Monitor digestibility and solubility characteristics for target species/formulations.

- Traceability: Batch-level CoA and retained samples enable audit trails.

- Multi-Site Consistency: Harmonized specs streamline cross-plant inventory and QA release.

Food Additive Codes: E339, E450, E451, E452

Food-grade phosphates are often referenced using “E-numbers.” The table below provides a compact orientation for common phosphate code groups

frequently encountered by product developers and regulatory teams.

| Code | Category | Typical Functions | Notes |

|---|---|---|---|

| E339 | Sodium phosphates | Buffering, sequestration, pH control, texture adjustment | Includes mono-, di-, and trisodium phosphates for diverse food uses |

| E450 | Diphosphates (pyrophosphates) | Leavening acid (e.g., SAPP grades), water-binding, texture control | Common in bakery and processed meat applications |

| E451 | Triphosphates | Sequestration, water retention, emulsification support | Often used in meat/seafood processing and dairy systems |

| E452 | Polyphosphates | Emulsifying salts, sequestration, stabilization | Broad functional toolbox, dosage and labeling vary by market |

Reminder: Always confirm permitted uses, dosage ranges, and labeling requirements with the regulations applicable to your specific market and application.

Quality & Compliance Checklists

Documentation

- CoA per lot with analytical methods clearly stated

- TDS, SDS in required languages

- Change-control policy; notification timelines

- Retained samples and traceability

Certifications

- GMP-aligned quality system; ISO-based QMS

- Food/Feed/Pharma statements as applicable

- Kosher/Halal certificates if business-critical

- Allergen/GMO declarations

Analytics

- ICP/OES or equivalent for elemental impurities

- Ion chromatography for anion profiling

- PSD curves; sieve analysis

- Moisture (Karl Fischer or LOD), pH, bulk density

For SMFP, align fluoride content and stability data with oral care formulation needs. For DCP, emphasize nutrient guarantees,

contaminant limits, and flow characteristics. Agree on acceptance criteria in your quality agreement to streamline batch release.

Learn more about our quality and compliance approach on the About GJ Phosphate page.

Sourcing Strategy: How to Choose a Phosphate Supplier

Selecting a phosphate supplier is ultimately about managing risk and optimizing cost-in-use. Beyond unit price, evaluate the supplier’s operational

reliability, documentation depth, logistics adaptability, and technical support. The following framework helps procurement and technical teams align on priorities.

1) Supplier Capability & Reliability

- Demonstrated capacity and on-time delivery performance across seasons

- Multi-plant or dual-route options for resilience

- Clear lead-time models; expedite policies for supply spikes

2) Quality System & Data Transparency

- ISO-based QMS and GMP-aligned practices where relevant

- Data-rich CoAs (assay, impurities, PSD) and rapid document turnaround

- Change-control discipline with formal notifications

3) Packaging, Handling & Storage

- Standard 25 kg bags and bulk FIBCs; liners with moisture barriers

- Palletization suitable for your warehouse equipment and climate

- Clear shelf-life statements and storage recommendations

4) Contracting & Risk

- Volume bands with service-level KPIs (on-time %, CoA accuracy, claim response)

- Indexation clauses where appropriate (energy, freight) with caps/floors

- Retention samples and corrective action protocols

modest improvements in dispersion, stability, or flowability can materially reduce total landed cost per finished unit.

Sustainability & Future Outlook

Sustainability has moved from optional to expected. Buyers increasingly request evidence of reduced energy intensity,

water stewardship, and packaging optimization. Phosphate manufacturers that invest in cleaner utilities, effluent treatment,

and smarter packaging are better positioned in modern RFPs.

Water stewardship

Waste minimization

Closed-loop practices

Recyclable packaging

Looking ahead, digital documentation portals, QR-coded CoAs, and real-time shipment tracking will become standard expectations—reducing friction

between supplier QA teams and buyer plants, and enabling faster root-cause analysis when deviations occur.

References & External Resources

- EFSA: Food Additives – Topic overview

- FAO Codex: General Standard for Food Additives (GSFA)

- PubChem: Sodium Monofluorophosphate

External links are provided for general reference; always verify the latest regulatory status and specifications for your target markets.

Why Partner with GJ Phosphate

GJ Phosphate is a specialist supplier of industrial and food/feed-grade phosphates, focused on consistency,

documentation depth, and application engineering. We align product selection with your process window, quality targets, and compliance roadmap.

Learn more about GJ Phosphate and our international supply capabilities.

Application-Matched Grades

From SMFP for oral care to DCP for feed and select pharma uses, we calibrate assay, PSD, and packaging to your formulation needs and climate.

Documentation-Ready

CoA, TDS, SDS, and regulatory support letters delivered fast. We maintain retained samples and follow a formal change-control process.

Reliable Logistics

Flexible pack sizes (25 kg bags and FIBCs), stable lead times, and forecast-based allocations to protect your production plan.

Contact GJ Phosphate

Visit Our Website

Need assistance with a current formulation or plant trial? Our technical team can review process parameters (pH, PSD, moisture, mixing time)

and propose adjustments to stabilize performance at optimal dosage.